Protective coatings do just that, they protect your building and assets. High performance paint combined with expert application of specialist finish layers offer both instant visual appeal as well as a means to simple long-term maintenance. All surfaces, including signage, can benefit from the preservation protective coatings offer against harsh weather elements, corrosion, UV degradation and graffiti.

Whether your property has simple elevations that can be painted with straightforward roller brush application or is a sophisticated infrastructure requiring swing stages, you most likely are able to prolong lifespan and tackle any deterioration through a professional approach to coating application.

Proper assessment of each substrate and elevation to accurately address the kind of protection your facility needs will ensure you achieve asset durability and simple maintenance despite exposure to harsh elements and risk of graffiti.

A quality professional protective coating application process should include:

- Substrate preparation including high pressure cleaning

- Removal and isolation of lead, asbestos and rust

- Specialist epoxy, polyurethane and anti-corrosion coatings

- Suitable applications for various façade, steel and cladding material

- Fire protection

In addition to a specific plan and application process, the work should be carried out by trained and experienced painters, and checked by accredited inspectors to ensure both application and outcome meets the required standards for protection and safety specifications. Particularly where food and manufacturing facilities are concerned, this should further entail the latest industry practices in environmentally-friendly application and achievement of dust-free surfaces. This is also true of work in confined spaces such as within water tanks and work at heights so you can be certain the work will be completed safely with expert knowledge.

Programmed has successfully carried out painting work using specialist protective coating for many customers to meet their gamut of varying requirements. These include the MCG Light Towers (VIC, Australia), Blue Scope Steel/Fluor (NSW, Australia) and Fulton Hogan (Auckland, New Zealand).

The bridge connecting Bluescope’s operating plant in Port Kembla with the main harbour had failing paintwork which contained lead, allowing rust to develop. The bridge was stripped of all its existing coatings, appropriately treated and repainted with specialist protective coatings to reduce future development of rust and degradation. The success of the project won it the Master Painters Awards for Excellence in the Environmental Management category.

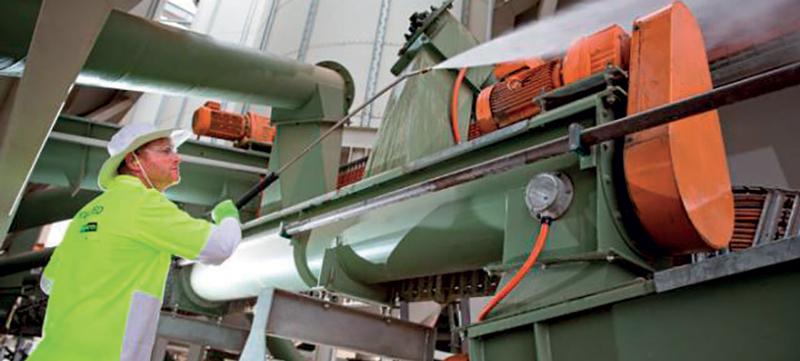

Fulton Hogan works with large volumes of aggregates and bitumen creating an abrasive environment for buildings and equipment at the facility. A long-term maintenance programme allows Fulton Hogan assets to withstand the rigorous work environment and maintain a clean and well looked after site. Given the nature of the surroundings, protective coating along with specialised access equipment plays a key role in the facility’s on-going paint maintenance.

At Victoria’s MCG, conservation of its six iconic light towers is paramount. Testing Melbourne weather and a busy sporting schedule that puts it in the constant limelight means the light towers require ongoing functionality and presentation from both an aesthetic and operational perspective. To maintain these instantly recognisable landmarks against wind, rain and the glaring sun, a combination of highly skilled painters and specialised coatings is necessary. These also provide protection against dirt and rust, and are part and parcel of its long-term preventative maintenance programme.

Be it maintenance or renovation, speak to us to start protecting your assets today. Visit our website to request an obligation-free quote.

FOR MORE INFO 0800 620 911