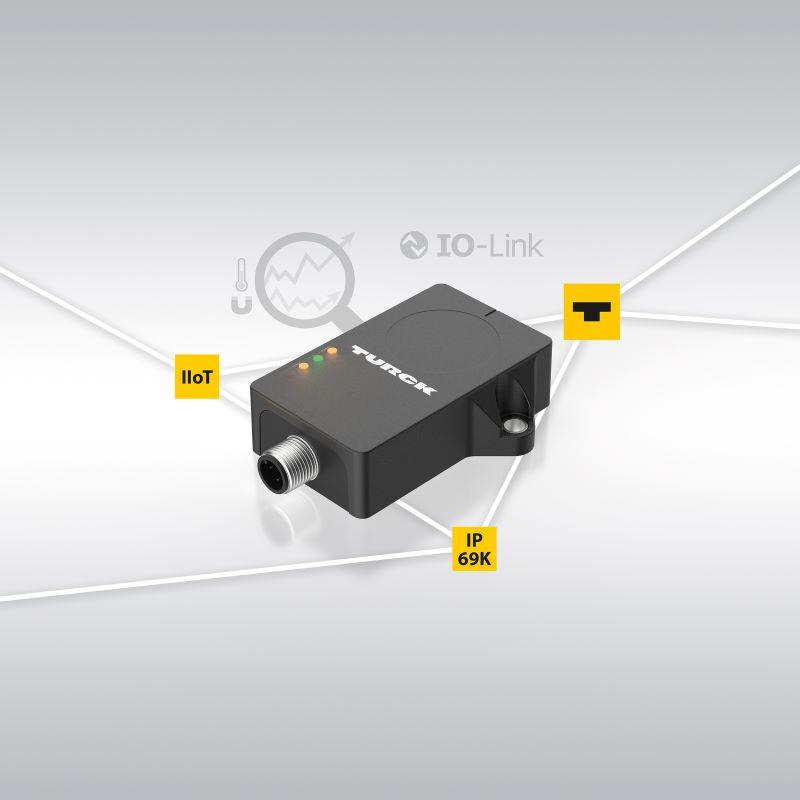

Turck's CMMT condition monitoring sensor detects magnetic field changes on three axes and thus creates new application possibilities.

The CMMT 3-axis magnetic field/temperature sensor with IO-Link is the third type of condition monitoring sensor that Turck has developed. Designed to be easy-to-use and retrofittable, it complements the existing range of CMVT vibration/temperature sensors and CMTH humidity and temperature sensors. The combined measurement of magnetic field and temperature with the CMMT enables simple detection of faults on motors or in processes with magnetic components. The new sensor also resolves applications that were previously impossible, such as the contactless detection of the rotation and movement of metal objects without visual contact such as an auger inside a steel pipe.

Thanks to its high sensitivity of five microtesla, the sensor also detects the earth's magnetic field, but can mask this if required by setting the parameters. The device outputs measured values individually or as a vector sum via IO-Link. Users can also assign two independent switching outputs. The CMMT supports the Smart Sensor Profile 4.1.4.

When commissioning the CMMT, users are supported by the Turck Automation Suite (TAS) Magnetic Field Monitor app. This application visualizes the sensor data live in the web browser and can be used via any Turck IO-Link master without additional software. The device functions are also set via TAS or other IODD interpreters. Besides the process values, additional information such as operating hours and switching cycles can also be accessed via the digital interface.

Web: www.turck.com.au