Nord Drivesystems have optimised the performance of their Unicase worm gear units, thus omitting the switch to the next size depending on the application. Lower wear increases the gear units´ (operational) reliability and service life.

Nord has increased the maximum torques of its Unicase worm gear units. The Nord development team thus achieved increased performance of 10 to 15 percent - without changing the gear units´ outer (connection) dimensions, or their general outer appearance. The reliable and economic drive solution offers higher performance without the need of adjusting existing customer configurations. As the housing sizes remain unchanged, the worm gear units will still be available as a drop-in solution for maintenance works or repairs. To save costs and installation space, smaller sizes can be selected according to the application, resulting in more constructive freedom in machine and system design.

“With the increased performance of our Unicase worm gear units, we could create enormous added value without additional costs for our customers”, Jörg Niermann, Head of Marketing at Nord Drivesystems, emphasises. “We owe this to the high expertise, the comprehensive technical know-how and the long-term experience of our competent development team.”

A masterpiece of engineering skill

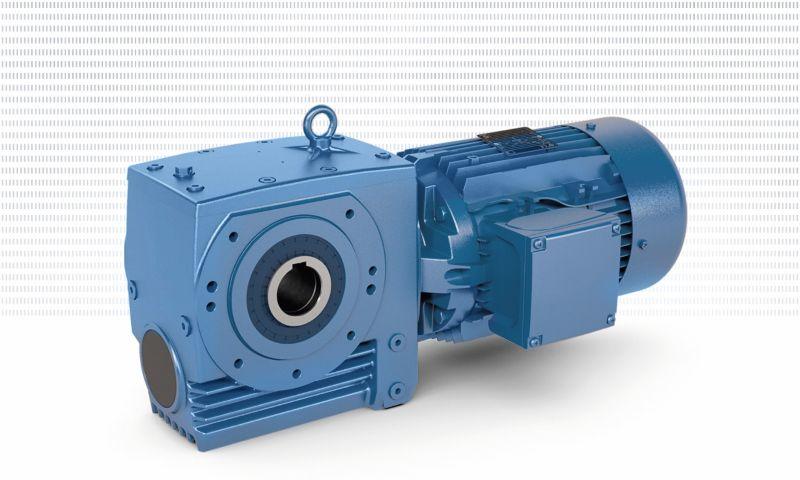

The (connection) dimensions have not changed, but in order to implement higher power ranges, Nord incorporated new worm shafts with larger bearing seats, as well as an additional reinforcement of the worm wheel itself. The current Unicase worm gear unit series offers a power range from 0.12 kW to 15 kW, and torques between 90 Nm and 3,000 Nm. Other product advantages include smooth and quiet running, high overload capacity and robust design. High axial and radial loads ensure high (operational) reliability and long service life.

The Unicase worm gear units in cast iron housings from Nord are available in application-specific versions: as hollow and solid shaft gear units, and for shaft, flange or foot mounting. The company´s electric motors can be added as an integrated solution. Motor mounting via an IEC/NEMA adapter is also possible.