Manufacturing for the future – now, NORD DRIVESYSTEMS has further cemented its commitment to Industry 4.0 by joining an esteemed panel of experts in Australia.

A powerful cohort known as Open IIoT sees prominent manufacturers, SMC Pneumatics, Beckhoff Automation, Balluff, ZI-Argus and NORD DRIVESYSEMS Australia addressing the complexities of Industry 4.0 and IIoT technologies.

By cutting down the jargon, the team looks to get to the real issues that its customers face and will work together to not only solve automation challenges but to demonstrate tangible customer savings.

The driving force behind NORD DRIVESYSTEMS for this particular project is its Managing Director, Martin Broglia. Martin says that meeting smart factory needs and staying ahead of the curve is key to the company’s success in the market. As a German-born company, NORD DRIVESYSTEMS is no stranger to the world of Industry 4.0 and its intelligent drive units have created quite the stir – both locally and abroad.

Martin says: “Today, there is a demand by more and more customers for IoT technologies to keep them informed, remain flexible and provide efficiencies. More than ever it’s about increased outputs, reduced inputs, more accuracy, more profits and more communication,”

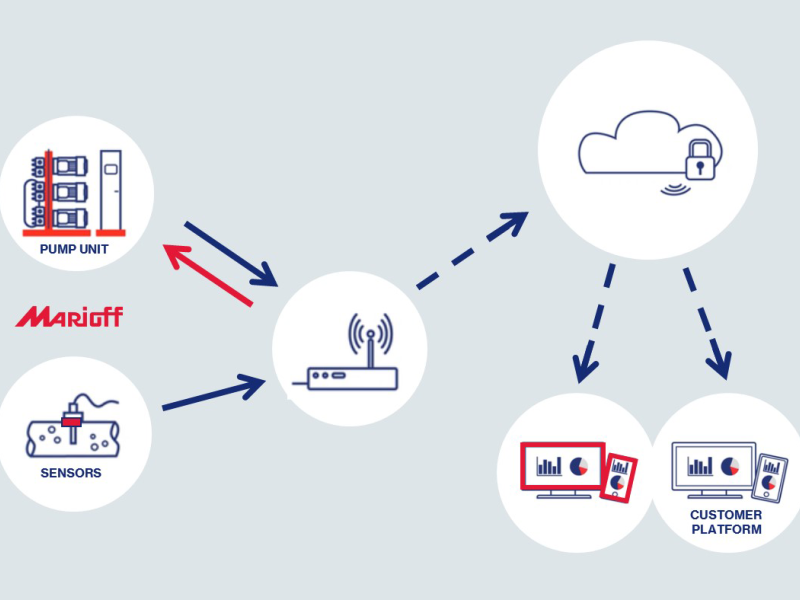

Further explaining their industry-driven solutions, Martin says that NORD DRIVESYSTEMS decentralized drive units are integrated with a PLC to control both simple and complex applications directly. “This in turn reduces the load on higher-level system control units and enables a modular system design and autonomous production units”.

NORD’s intelligent drive units can evaluate the application data and transfer it directly to a sequence control unit in real-time.

Recently, Martin spoke to the topic of Industry 4.0, saying that the company is well-versed to offer such solutions. “There is no extra hardware needed to enable these features on our VSDs as they are already embedded, can communicate to a higher control and can provide the data needed i.e. virtual sensors type information”.

Martin also notes that cost saving is the name-of-the-game at the moment and that customers are looking to save money and reduce their carbon footprint. “The reduction in cost can be accelerated for companies that have conveyor systems i.e. intralogistics, Food and Beverage etc. Our super premium efficiency motors, IE4, boasts up to 50% energy savings and has become very popular over the years”.

Martin believes that the adoption of Industry 4.0 technologies will accelerate rapidly in Australia over the next few years. “The benefits that NORD is seeing overseas cannot be further ignored otherwise we will be left too far behind”.

NORD DRIVESYSTEMS will be exhibiting at Auspack 2019. Look-out for them as well as the Open IIoT stand at next year’s show.