With a demand for real-time communication by its customers, Nord Drivesystems has spent years investing and gearing up for smart factory automation, says the drive technology company.

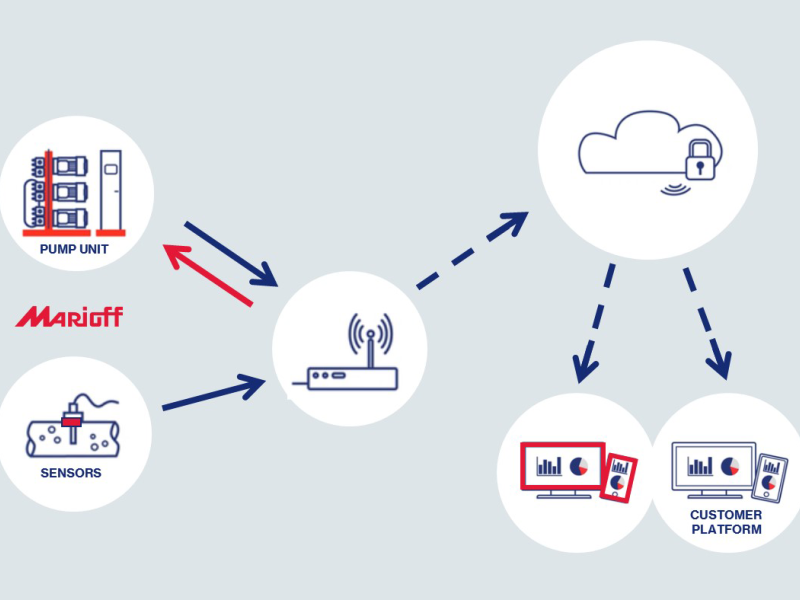

As a German company, the trend for IoT technologies has been in the spotlight for a number of years and in Australasia, the uptake is accelerating rapidly. To answer to the call, Nord now offers solutions for making real-time drive data available in a cloud environment. Here, all drive axes can be monitored from anywhere in the world via an internet connection.

According to Managing Director for Nord Australia, Martin Broglia, AUSPACK 2019 is the perfect platform to showcase its IoT solutions. “This intelligent drive has been thoroughly tested and has proven to perform reliably in a drive network, utilizing standard interfaces and components”.

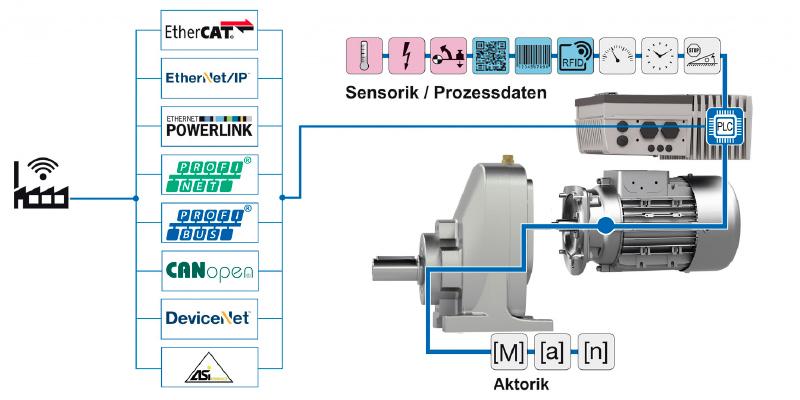

“AC vector drives and motor starters controlled via Profinet simultaneously transmit live status data in UDP packets, on the same bus line, without affecting regular control communication,” he continues.

These cloud-enabled drives send data about their power consumption, speed, and voltage, as well as their status. “Tunnelled through a Siemens PLC, all of this in-formation is transmitted to an IoT gateway and on into the cloud. Status data can then be analysed for energy profiling, asset management, and remote maintenance purposes. Of course, any overload and error states can be visualised,” says Broglia.

In addition, the intelligent drives can also transmit additional application data into the cloud at any time – for instance, data of connected sensors and actuators. Moreover, other parameters can be derived from available status data, notably current oil temperatures. Nord has successfully validated this in initial tests. “Such data allows for conclusions about lubricant aging that can be used for predictive maintenance.”

Nord continues to work on and further refine IoT-related and Smart Factory concepts, and the company recently joined forces with several prominent Australian manufacturers to launch ‘Open IIoT’ who will also be exhibiting at AUSPACK 2019. “By cutting down the jargon, the team looks to get to the real issues that its customers face and will work together to not only solve automation challenges but to demonstrate tangible customer savings,” says Broglia.

Visit us at AUSPACK 2019 (Stand G075).