NORDAC BASE: Robust frequency inverter for process engineering

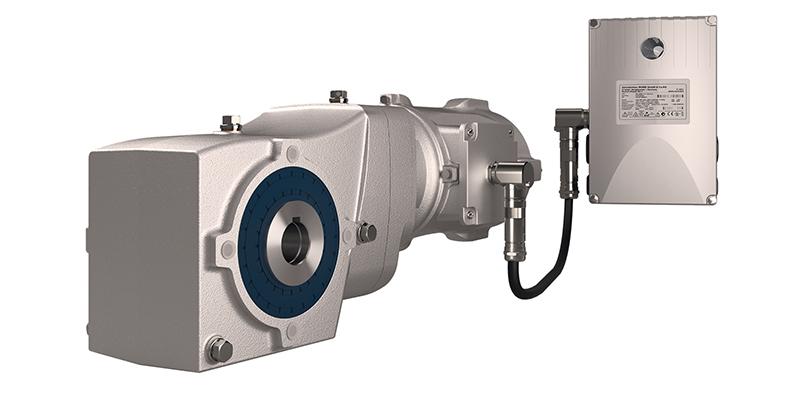

The NORDAC BASE – SK 180E, offers an ATEX-compliant, decentralised frequency inverter that not only allows for an economical operation but also comes in protection class IP 69K, for complete sealing of the housing. This is particularly appealing for processing applications which requires frequent high-pressure cleaning.

Recognising that many applications today do not fully utilise the immense scope of modern frequency inverters, NORD fills the gap between simple motor starters and full featured frequency inverters with its NORDAC BASE – SK 180E.

This recently launched robust inverter is specifically designed for simple applications and can be mounted (decentralised), outside a switch cabinet. The compact frequen-cy inverter concentrates on the essential functions for pumps and conveyor technolo-gy (PI / speed control, energy saving, communication with peripherals) and results in significant savings - in both purchase and performance.

The NORDAC BASE includes power ranges up to 2.2 kW and offers easy commis-sioning and operation. In addition, it is flexible with regards to accessories, function, and a number of communication interfaces make it compatible with all common bus systems.

The IP 69K housing offers the ultimate protection against the ingress of dust (dust proof) and jets from high pressure water and steam cleaning. The SK 180E is de-signed to control synchronous and asynchronous motors. Energy-efficient operation is possible due to its energy saving function for partial load operation.

Much L=like all NORD frequency inverters, the NORDAC BASE comes with an inte-grated PLC. The intelligent drive electronics reduces the load on the higher-level sys-tem control unit and allows for a modular plant design.

The SK 180E can also be modified for operation in explosive environments; depend-ing on the area of application (conductive or non-conductive dust), the modifications also include the replacement of the transparent diagnostic caps with a version made of aluminium and glass to allow for operation in a hazardous area.

NORD DRIVESYSTEMS Company background

With more than 3,600 employees, NORD DRIVESYSTEMS has been developing, producing and selling drive technology for over 50 years now and is one of the global leaders of full-service providers in the industry. In addition to standard drives, NORD delivers application-specific concepts and solutions for special requirements such as energy-saving drives or explosion-protected systems. In financial year 2016, annual sales amounted to 560 million Euro. NORD now has subsidiaries and sales partners in 89 countries worldwide. The dense sales and service network guarantees optimal availability, enabling short delivery times and customer-oriented service. NORD produces a very diverse range of gear units for torques of 10 Nm up to over 250 kNm,

provides electric motors in the power range of 0.12 kW to 1,000 kW and manufactures frequency inverters and the required power electronics of up to 160 kW. Inverter solutions are available for conventional control cabinet installations as well as for decentralised, fully-integrated drive units.