US-based INFOR has stepped up its customer focus in Asia Pacific and opened a regional head office in Singapore. The company develops business cloud software products for companies in industry specific markets, building complete industry suites in the cloud that help manufacturers overcome market disruptions and achieve business-wide digital transformation. By: Helen Masters, Senior Vice President and General Manager, Infor Asia Pacific.

Smart factories, digitisation, and the Internet of Things (IoT) are all hot topics in the manufacturing sector that generate considerable buzz – and some consternation. These disruptive technologies are exciting, yet the complexity can also be overwhelming.

But with a practical plan of action, including options with minimal disruption and low-risk, even those who have been reluctant to embrace next-generation technology can get started on the journey.

Easing In

Equipment can be modernised, processes upgraded, and new technologies adopted gradually, all while controlling risk. With a gradual approach, manufacturers can turn to edge applications, hybrid solutions, and a phased rollout to build confidence and gain buy-in from the various teams.

Where Are We Going, Anyway?

Once your company has moved into the “acceptance stage,” it’s time to decide your goals for your investment and tactics to get there. Most digital technologies, like IoT, are not out-of-the-box solutions you simply plug in. A customised approach is critical. Setting a well-defined plan with measurable milestones will help eliminate project ambiguity. Focus on building a plan that is practical, doable, and cost-effective.

For many companies, picking one basic goal offers the chance to get started and prove key concepts. Examples of viable Phase 1 goals include:

• Prevent unexpected down-time and keep shop floor assets running.

• Better manage inventory levels with fewer stock-outs.

• Meet customer demand for highly personalised products.

• Improve customer engagement and build brand loyalty.

• Speed time to market of new product introductions.

Note that broad goals, like “double profits” or increase sales” are not on this list, as they are too generic to develop one digital initiative that would lead to success.

Address Funding Issues

If you’re not ready – financially or otherwise – to make a huge investment in IT solutions, you could start small with cloud deployment, which uses a subscription model and thus lacks the large one-time capital investment. It allows you to reap the benefits of cloud computing while protecting critical customer data – and you can move forward while easing anxieties among stakeholders.

Another way to overcome funding issues is to use the savings generated for Phase 1 to Phase 2 projects. In most organisations, there are opportunities for easy wins, usually involving deployment of a point solution that can produce major savings.

Here are some areas where you can quickly see savings:

• Business intelligence tools for tracking real-time results.

• CRM solutions to manage customer relationships.

• Shop floor scheduling, planning and time-tracking.

• Field service management, tracking warranties and service agreements.

• Inventory management to improve accuracy.

Prioritise

Building the business case is an important next step, so start by prioritising with must-have basics for modernising your operations. Think of these as your foundations for growth:

• End-to-end visibility.

• Mobility.

• Attractive, easy-to-use interfaces.

• Self-service reporting workbenches and dashboards.

• Mod-free, the days of heavily modified software is over.

The nice part is that these elements can be achieved with one modern ERP solution, whether with your existing ERP or through an upgrade.

Should you go bigger?

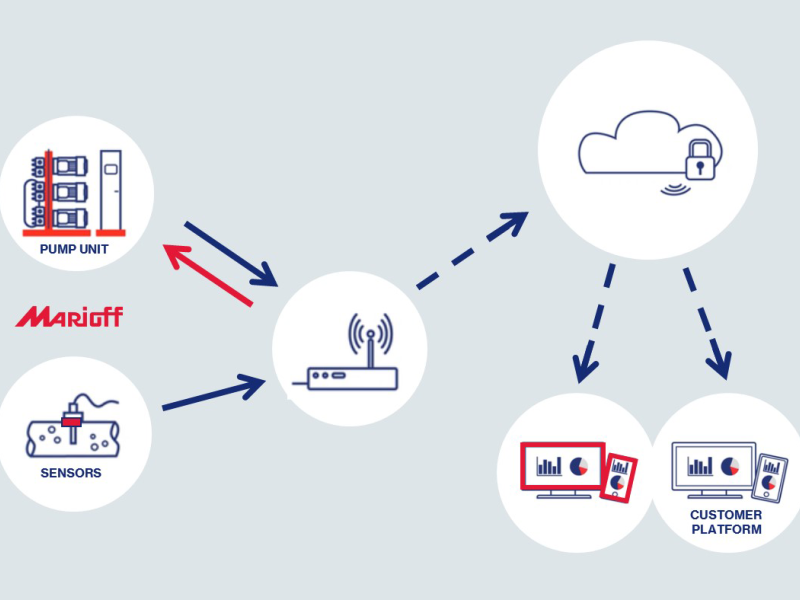

Some new aspects of digitisation require a leap of faith. Some manufacturers are building new revenue streams and business models. Offering the product as a service or outcome-based solution, rather than selling the product, is gaining traction in some industries, especially ones where the traditional product is high-value like cranes, tractors and road building equipment. However, this often requires new strategic thinking and integration of unfamiliar technologies.

Deciding whether to increase services and/or scale can be a difficult decision – a decision made easier by taking hold of the competitive landscape. Seeing that competition is expanding rapidly and prioritising innovative thinking will force your organisation to quickly adapt.

But instead of focusing on other companies, it’s better to prioritise the customer – analyse their needs and provide solutions. For example, if the customer expects Amazon-style fast-tracked, two-day shipping and delivery, then companies need to adopt strong supply chain management software that digitally connects the moving pieces of their business. With complete supply chain visibility and real time insights, organisations can not only have better control of their product, but also provide control to the customer, allowing them to track progress in real time.

Final Thoughts

It’s an exciting time to be in manufacturing, but the range of opportunities and technology options can also make it overwhelming. With a pragmatic view, manufacturers can overcome common barriers, set realistic goals and find the funding to make innovative ideas successful.