A New Zealand Apprenticeship in Plastics Engineering has opened the door to a wealth of unexpected opportunity for Dunedin’s Wesley Lewis.

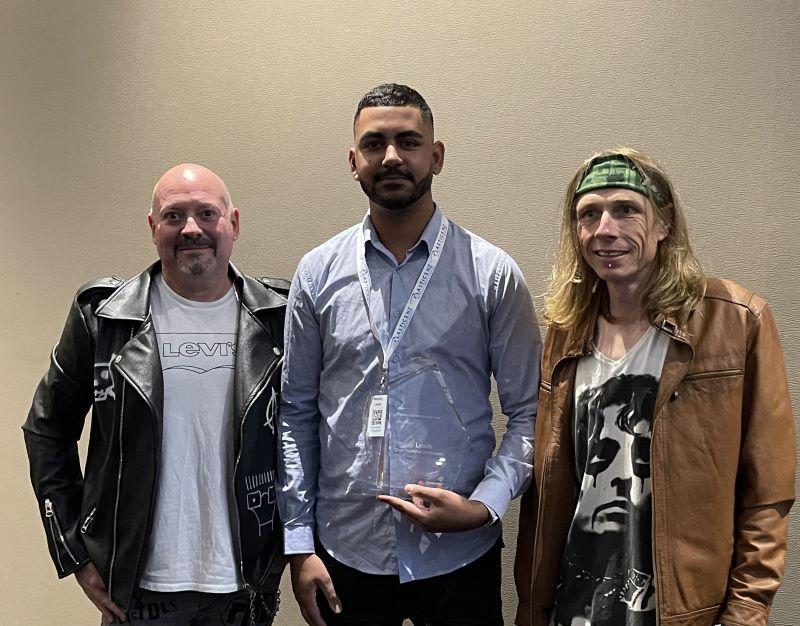

The talented 27-year-old has just been named Plastics Apprentice of the Year 2023, and now he’s on the fast track to success at food packaging business Packit Packaging.

Since joining Packit as a casual packer Wesley has made his mark, impressing General Manager Jamie Hodgins with “his can do attitude, work ethic and high standards of workmanship”. Now he is continuing to blaze a trail, developing his managerial capabilities through the Dunedin Leadership Academy.

“Wesley went from packing parts into cartons in our factory, to now managing the plant and daily production over the space of four years through his apprenticeship,” says Jamie. “He is a key member of our business and we’re looking forward to moving him into a managerial position in the future.”

Currently in the role of Supervising Production Technician, Wesley is responsible for the day-to-day operations of the factory and the technical staff workload, also overseeing the training of Packit’s newest plastics apprentices. Although he never intended to go down the management path, Wesley says his quick career progression has come as a pleasant surprise.

“As a kid I always enjoyed tinkering with things and my apprenticeship gave me the chance to immerse myself in the technical side,” says Wesley. “It’s very easy to look at a machine and assume you know what it’s doing, but there’s actually so much to it, like maintenance, how it operates, and chemical breakdowns. The apprenticeship covers all that and gives you a really good broad understanding.

“Now I’m working my way up in the company and going down the leadership route. I started out with no management skills at all, and it has been a real eye opener learning how different people operate.”

Does he miss the tool time? “Yeah I do a little bit, it’s very rewarding. But I’m always on hand for higher level diagnostics when my team needs me, and Jamie has me doing more of the bigger projects now which I really enjoy. Earlier this year we installed a whole new chiller system, and I did all the labour around that which was pretty satisfying.”

It was also “pretty satisfying” when he found out he had won Plastics Apprentice of the Year at the recent New Zealand Plastics Industry National Conference.

“It was a bit of a shock to be honest, but it means a lot to have all my hard work and effort recognised. There were some stressful times during my apprenticeship. I loved the technical side, but I found the business side of things pretty challenging. Going into it I had no knowledge of business systems, flow systems and stuff like that, but it does all get explained really well throughout the training.”

With the mentorship of a great employer and a dedicated Competenz training advisor for additional guidance, plastics apprentices are well supported as they work their way through their Level 4 qualification.

Quarterly visits, phone and email assistance, marking of units, study groups, and drawing classes are just some of the support offered by Competenz training advisor Stuart Hewson who says he is “very proud” that Wesley’s work ethic and high levels of achievement have been recognised at a national level.

“Wesley has got a lot of enthusiasm for learning and the plastics industry, and genuinely shares his knowledge and experience with his trainees,” says Stuart. “He is the future of the industry, the next business manager and owner, and future trainer in such a technical area.”

Although Wesley didn’t realise it at the time, the New Zealand Certificate in Plastics Engineering (Level 4) has been the perfect springboard to an exciting career.

“People think that if you get a plastics apprenticeship you only ever work in plastics but that’s not the case,” he says. “It’s very engineering based, it’s very broad and there are lots of different routes you can take. I for one, thoroughly recommend it!”