With decades of experience in developing customized solutions for the most demanding mining applications around the world, Bonfiglioli offers its customers a wide range of solutions. From crushing to slurry processes to earth moving applications, Bonfiglioli designs and develops integrated solutions built to take on the harsh and dusty environments – typically found in mining applications.

Martin Broglia, Managing Director of Bonfiglioli Australia/ New Zealand adds: “Our final drive, gearbox, gearmotor, motion and control solutions have been well received by the market. Today, our range of products is one of the broadest available in the world - with torques ranging from 13 Nm to 3,000,000 Nm.”

Heavy-duty Sector Privy to Preventable Issues

The heavy-duty sector is privy to downtime associated with maintenance issues. “This is a challenge that companies in the mining, quarry and other heavy-duty sectors grapple with on a regular basis” says Martin.

“Any downtime can be costly; in the heavy-duty sector in particular, downtime can quickly add up. The old saying ‘time equals money’ couldn’t be more apt. Anything operating on a mine needs to be robust as possible, therefore, doing ones’ research is key.”

He adds that its important not to be short-sighted when making an investment. “You might spend less on an inferior product in the short-term, but the effects could be felt for years to come. When purchasing a quality product, you will spend more initially but the benefits to your bottom line will greatly exceed this”.

Bonfiglioli’s Solution for Feeders and Conveyors

Feeders and conveyors transport materials from one stage of the mining process to the next.

Bonfiglioli is an expert on issues related to these applications: the high breaking torque required at start-up, the high load shocks caused by material drops and the dusty environments in mines are just some of the challenges that Bonfiglioli’s products can successfully overcome.

“We provide complete solutions for feeders and conveyors with integrated base plates and torque arms that are protected against harsh environments. This can include special seals and paints to simplify machine design for our customers.”

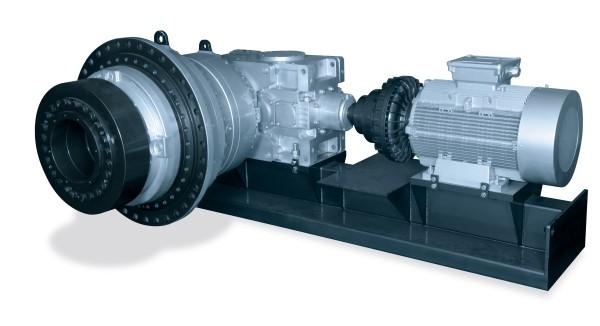

Martin adds that a suitable option for this application is the combination of planetary and helical bevel heavy duty gear units. “The 3/H Series offers a unique combination of high torque density (associated with planetary gear units) and the robustness and high speed of helical bevel heavy-duty units”.

He adds: “This configuration can provide great power transmission in a very compact space, thanks to its angular layout. The 3/H Series can also come with a set of features such as hydraulic couplings or cooling circuits, adapted according to customers' needs.”