For the past four years, the global economy has faced difficulties. Extended raw material delivery times, high energy prices, challenges in key industries, fewer orders, and transportation difficulties - many related to the outbreak of war in Ukraine - are just some of the challenges that manufacturing companies have been dealing with since 2020. In times of uncertainty, reducing production costs will be particularly important for many companies, as such actions can ensure the continuity of their operations. Seco/Warwick solutions perfectly illustrate how these actions can be implemented in practice.

“Efficiency and savings in production have become key factors influencing the success of a company. Companies that can produce more efficiently while controlling costs gain a market advantage and acquire a crucial edge in difficult times. At Seco/Warwick, we are well aware of this, which is why we are constantly working on solutions that will support our partners in this mission,” - says Sławomir Woźniak, CEO of the

Efficient Use of Resources

Resources, both human and technological, are the foundation of every production process. Their optimal use translates into increased operational efficiency and cost reduction. One example of a tactical improvement is the addition of Furnace/Plus, an intelligent process management centre that allows users to optimise the workflow of equipment and personnel, minimizing waste, and improving efficiency. The system facilitates the efficient use of energy and raw materials, supporting the economy and ecology of production, using the data collected to analyse trends, assess results, and provide the foundation to make strategic decisions.

“Thanks to Furnace/Plus, companies can reduce energy and raw material consumption while increasing productivity, significantly lowering production costs. But we can also use resources efficiently through specific innovations. For companies involved In aluminium processing, we have designed the Vortex 2.0 coil annealing system, which provides a 35% reduction in heating time compared to traditional technologies, thereby reducing operating costs and CO₂ emissions. It also ensures high energy efficiency and better use of available resources, lowering production costs. These systems are already operating in the largest aluminium processing plants in the world, and their implementation can be seen as a forward-looking approach to what is happening in global markets,” - said Piotr Skarbiński, Vice President of the Aluminium and CAB Products Segment at Seco/Warwick.

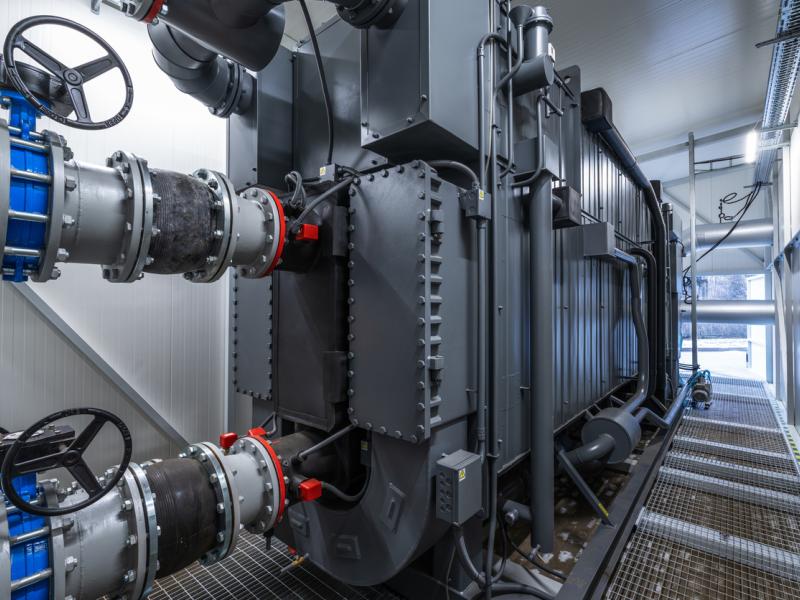

Heat Recovery

Another money-saving solution is to equip hardening plants with an installation that recovers waste heat from production processes. This process involves capturing the heat generated during heat treatment processes and using it to power other production processes, heat rooms, and provide hot water.

“This not only helps reduce energy costs but also makes us independent of gas supplies. It also brings environmental benefits by reducing CO₂ emissions, for example. We are installing more and more of these types of installations for partners who are paying closer attention to reducing costs,” - added S. Woźniak.

Preventing downtime

Unplanned downtime is one of the biggest sources of production losses. Eliminating it through process monitoring and proactive maintenance actions brings tangible savings. Once again, Seco/Warwick’s intelligent system, FURNACE/PLUS, comes to the rescue. Its advanced features include real-time equipment condition monitoring, which allows for predicting potential failures; proactive maintenance planning, which minimizes the risk of unexpected downtime; and process data integration, which enables quick response to changes and optimization of actions.

Implementing modern technologies

Modern technologies create solutions with increased efficiency and savings by shortening process times, reducing energy consumption, and eliminating unnecessary costs. Among the solutions that respond to the needs of contemporary manufacturers, several deserve special attention.

“Many manufacturers praise their equipment. But at Seco/Warwick, we don’t make empty promises. We have precisely calculated the cost optimizations resulting from the use of our equipment. The JetCaster furnace revolutionizes casting processes. It ensures a reduction in crystallization time by up to 50%, enabling faster production. Additionally, it reduces energy consumption by up to 40%, and with comparable energy use, we can produce twice as many castings. These are figures that capture the imagination,” - added S. Woźniak.

But JetCaster is not the only example of innovative technology that is changing production techniques. Pit-LPC is an alternative to traditional gas carburizing, producing a process time reduction of over 60%, which reduces energy costs. Additionally, implementing this technology effectively allows users to replace up to three atmospheric furnaces with one vacuum furnace, reducing both investment and operational costs.

Vacuum technologies ensure minimal process gas consumption during carburizing, enable the use of higher process temperatures, and thus shorten process times. One of the engineering tools that calculates, among other things, the demand for process gases is the SimVaC program, developed by the Lodz University of Technology in cooperation with Seco/Warwick. The program enables users to design each vacuum carburizing (LPC) process cycle by selecting optimal process parameters to achieve the required technological result at minimal cost with maximum efficiency.

“An example of equipment that increases the efficiency and savings of production plants is our two- and three-chamber vacuum furnaces, the CaseMaster Evolution. These systems operate using comprehensive vacuum carburizing with optional oil or gas quenching for large-scale and mass production. This solution increases efficiency and minimizes the waiting time for subsequent production stages, allowing for faster order fulfillment,” - commented Maciej Korecki, Vice President of the Vacuum Furnace Segment at Seco/Warwick Group.

Another solution is Super IQ, a hybrid of vacuum and atmospheric technology, allowing users to take advantage of the benefits of vacuum carburizing and traditional oil quenching. The ZeroFlow nitriding technology, on the other hand, allows for a reduction in ammonia consumption by up to 12 times, which lowers process costs. It also significantly reduces environmental impact by decreasing the use of process gases and the emission of post-process gases.

Reducing costs in manufacturing enterprises requires a holistic approach that combines efficient resource utilization, downtime prevention, and the implementation of modern technologies. Seco/Warwick solutions, such as FURNACE/PLUS, JetCaster, Pit-LPC, Vortex, and ZeroFlow, demonstrate that an innovative approach to production management can bring tangible economic and ecological benefits. This proves that investing in future technologies is not only a way to reduce costs but also to build a competitive advantage in a dynamically changing market environment.