How the choice of consumables and spare parts can impact the ongoing integrity of a compressed air system.

With some businesses still limiting their capital expenditure, maintaining the integrity of an existing compressed air system has never been so important. Kaeser Compressors discusses why opting for genuine spare parts and consumables when maintenance is required will play a pivotal role in achieving this outcome.

When you invested into your existing compressed air system, you did your homework. You researched your options. And, after weighing up the pros and cons you selected and invested in your compressed air system. The big decisions were made. Or so you think. As Peter Eckberg, the Managing Director at Kaeser Compressors New Zealand: “In the end, a compressed air system will only be as good as the maintenance it is given. Unfortunately, it is not a piece of equipment that you can set and forget about indefinitely. It does require periodic attention, and aside from following the original equipment manufacturer’s (OEMs) service interval recommendations, your choice of spare parts and consumables is critical. It is critical to ongoing compressed air availability, as well as in achieving the ongoing air quality level required for the application. It is also critical to the reliability, efficiency and safety of the equipment.”

The not so genuine options

From replacing the air filter and oil filter right down to the choice of lubricant, there are a number of consumables that need to be periodically changed – in a rotary screw compressor – for example. And, there are numerous options available when it comes to replacing these consumables as Eckberg continues: “Just head to a search engine and type in the manufacturer’s name and ‘consumables’, and you will be presented with copious websites that want to sell you compressor parts and lubricants – with some even claiming they are 100 percent OEM compatible. In other words, these consumables are not manufactured by the OEM. Here I can only talk from Kaeser’s perspective, but the only websites that you will find promoting genuine Kaeser spare parts and consumables, will be a Kaeser website or one of our authorised distributor websites. Unfortunately, a Latin term comes to mind – ‘caveat emptor’ – or’ let the buyer beware.”

So, what are the concerns with using non-OEM consumables and spare parts?

“Let’s take the example of a rotary screw compressor. The lifetime of the compressor, its overall performance, reliability and safety – as well as its maintenance requirements will all be impacted by whether you choose to replace the consumables with genuine or non-genuine parts. The compatibility of non-genuine consumables and spare parts with your compressor is one factor that will have a huge bearing on its resultant reliability and safety.

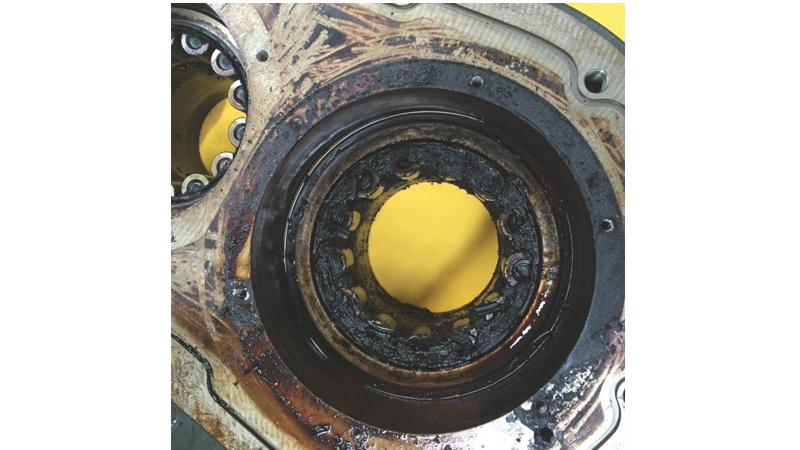

“As they say, a picture says a thousand words, so here’s just one example of what we’ve seen happen to Kaeser equipment when non-genuine consumables were used.

“The photo shows a compressor block (airend) bearing that was blocked full of oil sludge. Why? Infrequent oil changes and poor filtration are partly to blame, but also this has been caused by using non-genuine oil. This has allowed contamination into the compressor block which has mixed with the lubricating oil. The oil therefore lost all of its lubricating abilities which caused premature wear to the internal rotating components.

“Only genuine OEM spare parts will have been rigorously tested by the OEM with the compressed air equipment. The durability, performance, efficiency, safety or even the compatibility of non-genuine parts will not have been tested with the compressed air equipment. Therefore, there is no way of knowing how non-genuine spare parts will interact and how they may affect the ongoing integrity of the compressed air equipment. As a result, it’s possible that they could compromise the efficiency, reliability and safety of the rotary screw compressor as well as the air quality required.

“It’s also worth bearing in mind that only the OEMs genuine spare parts have been designed to meet the demands of the applicable operating conditions, quality tested to ensure the best possible performance and, designed to assure the life cycle is commensurate with the maintenance intervals.

“You should also consider that selecting non-genuine parts – which are not recommended by the OEM – may well void the manufacturer’s warranty. This could become costly if a fault occurs that would ordinarily have been covered under the warranty.

“It is of course possible to take the hassle out of selecting spare parts and organising service – or to be able to quite literally ‘set and forget’ your compressed air system – by selecting a comprehensive service package such as our Sigma Smart Air. Here remote diagnosis and data-based, predictive maintenance can be realised. This saves the user both time and money, while ensuring the availability of the compressed air supply.”

Details, Ph: 0800 447 820; nz.kaeser.com