Hydraulic cylinders are required to operate in a variety of applications and environmental conditions, including exposure to abrasives, debris and both high and low temperatures SKF offer a comprehensive range of fluid power seals made from high quality materials and with optimised seal designs to meet application requirements. Rigorous testing in some of the harshest environments demonstrates why SKF is a market leader in hydraulic seals.

The SKF hydraulic seal range covers all the major sealing components in light to heavy duty cylinders, with each seal type being designed and manufactured to SKF’s highest quality standards.

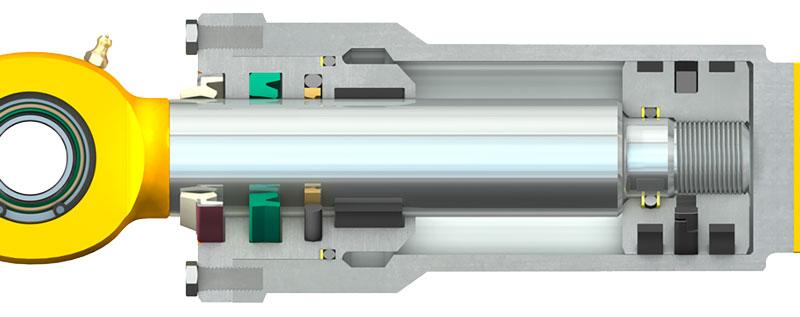

SKF wiper seals (also known as scraper, excluder or dust seal) are excellent at preventing contamination and external debris from entering the cylinder assembly. The wiper seal is fitted to the external side of the cylinder head. The outside static sealing of the SKF wiper within the recess of the cylinder head is important to avoid contamination entering the cylinder .

Wiper Seal features:

- Wide range of profiles, sizes and materials for a wide variety of operating conditions and applications.

- Press-in and snap-on wipers.

- Single acting and double acting wipers.

The SKF piston seal range maintains the sealing contact in a sliding motion between the piston and the cylinder bore. Pressure acting on the piston seal to extend or retract the rod can be in excess of 400 bar (5800 psi) resulting in the seal contact force increasing dramatically, therefore the surface properties of the piston seal are critical.

SKF Piston Seal features:

- Single and double acting seals

- Wide range of profiles, sizes and materials for a wide variety of operating conditions and applications

- Low friction design

- Optimised compatibility with operating fluids

In addition to the sealing function of the rod and buffer seals, rod seals are designed to provide a thin lubrication film on the piston rod that lubricates themselves and the wiper seal. External forces acting on the rod can cause pressure peaks creating the risk of gap extrusion which can be avoided for rod and buffer seals by using SKF anti-extrusion rings.

SKF Rod and Buffer Seal features:

- Rod seals provide a thin lubrication film that lubricates themselves as well as the wiper seals and inhibits corrosion of the piston rod surface.

- Integrated anti-extrusion ring designs.

- Optimised wear resistance.

- Wide range of profiles, sizes and materials for a wide variety of operating conditions and applications.

Seal materials play a major role in the performance and service life of hydraulic seals. Generally, hydraulic seals are exposed to a variety of application and working conditions, such as a wide temperature range, contact with various hydraulic fluids and the outside environment, as well as high pressure and contact forces. An appropriate seal material must be selected to achieve a reasonable service life and service intervals. A wide variety of hydraulic seal materials from four major polymeric material groups is available from SKF:

- Thermoplastic elastomers, such as poly-urethane (TPU) and thermoplastic ether-ester block copolymers (TPC).

- Rubbers, such as nitrile (NBR) and hydrogenated nitrile rubber (HNBR), fluorocarbon rubbers (FKM, FPM).

- Polytetrafluorethylene (PTFE) and its compounds.

- Rigid thermoplastics and thermosets and their composites.

The benefits of using the SKF Hydraulic Seal range include:

- Improved sealing performance

- Extended system service life

- Increased productivity

- Reduced maintenance costs

- Increased mean time between failures (MTBF)

- Optimised design and development of fluid sealing systems for custom applications

For information email: customerservice.

nz@skf.com or visit our website www.skf.com