How retrofitting can help manufacturers prosper during the slowdown

The Asian Development Outlook, the flagship publication of the Asian Development Bank, has predicted that regional growth in developing Asia will decline sharply in 2020 due to the impact of coronavirus. The report predicts a growth rate of 2.2 percent, which is 3.3 percentage points lower than the prediction it made in September 2019. Retrofitting can play a role in helping manufacturers ride this slowdown in growth, maintaining production output and reducing costly downtime.

With growth forecasts being slashed, many manufacturers focus on external factors likely to impact on their business such as volatile raw material costs and supply chain disruptions. However, implementing a structured retrofitting programme to internal equipment and systems is a frugal way to safeguard production output, optimise efficiencies and reduce downtime.

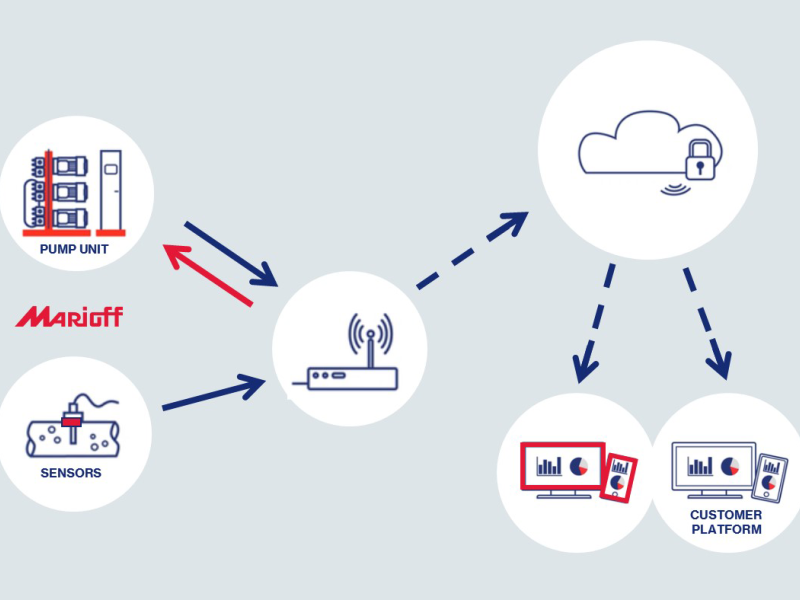

There is a common misconception that to remain competitive in today’s manufacturing industry, and particularly during a period of economic uncertainty, a factory must be installed with the latest state-of-the-art technology. Retrofitting enables manufacturers to transform legacy equipment into smart machines, bringing them up to Industry 4.0 standards with the capabilities to gather, store and share information with other systems across single or multiple sites.

Many machines in well-established production lines, which may be between 15 and 30 years old, can still perform their main functional tasks successfully. However, they do so less efficiently than their modern-day counterparts. For example, they don’t have the same level of computing power, enough memory capacity to record and store the relevant data. In many cases, these machines also use data formats and protocols no longer used by today’s PLCs and industrial PCs. Facilities relying on ageing, unconnected infrastructure can suffer huge production losses if components fail.

Retrofitting extends the life of legacy equipment, adding new capabilities and functions that were absent in the original design. It improves energy efficiency levels, processing speeds and machine reliability. It also enables a manufacturer to be smart about predictive maintenance and condition monitoring, which in turn increases efficiencies, reduces downtime and cuts costs and the need for maintenance.

For example, retrofitting a sensor to a motor will enable it to run more efficiently and reduce the amount of energy it consumes. Replacing old components with new more advanced ones enables machines to collect, communicate, analyse and compare data with others in the network.

In terms of capital expenditure, the cost of retrofitting is significantly less than buying new Industry 4.0 ready machines. Indirect cost savings can be made too.

Decommissioning old equipment and installing replacements requires substantial downtime, which can be reduced by opting for a retrofit instead. Similarly, disruption to the working environment is minimised, reducing any negative impact on production output.

Well-structured retrofitting, rather than random patching, is the best way to future-proof your factory. Simply monitoring whether equipment is on or off and how much the system is producing can give you an indication of effectiveness and performance.

Knowing which machines pose the greatest risk to productivity in the event of unplanned downtime is also key when planning a retrofit programme. Quick gains can be made by connecting older machines to the internet using a sensor that connects to a controller, which collects data and converts it in a usable format so the information can be made available to the rest of the factory network.

The Asia Pacific region is in a relatively strong position to ride the impact of coronavirus and it is predicted that growth will rebound strongly in 2021. Manufacturers should be encouraged by these predictions. In the meantime, retrofitting offers them an affordable and practical way to navigate a period of lower growth.