The air-operated double diaphragm (AODD) pump is one of most versatile and commonly used pumps in the world.

These pumps are generally simple to operate and offer good flexibility for a wide range of industrial applications.

However, they also have a reputation for high air/energy consumption, high maintenance costs,

downtime, high noise, as well as complexity when it comes to servicing or ordering replacement

parts.

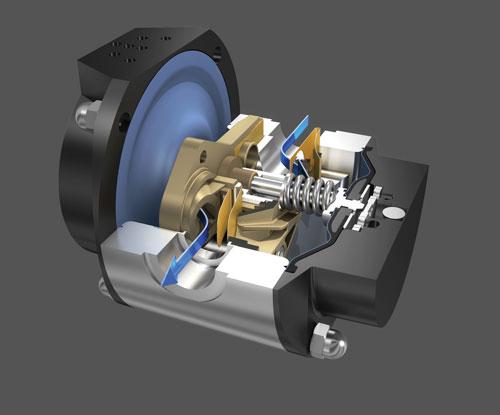

Albin, a leading French manufacturer of hose, gear and lobe pumps, has developed a revolutionary AODD pump that – compared to generic brands – offers up to 70 per cent lower pulsation,

lower energy consumption/better efficiencies, lower noise output, and three to five times longer operation time between service intervals.

All of these improvements result in significant operational and maintenance cost savings to the end user.

With the Albin AD pump, energy use is reduced by means of a reduction of Revolutionary air-operated double diaphragm pumps friction and current losses through a central flow path and unique air valve design. The results are lower costs through heavily reduced energy consumption and, as a consequence, lower environmental impact.

The reduced friction and current losses also reduce pulsation.

Independent tests at the Technical University of Stockholm in Sweden have shown that AODD pump users can reduce their compressed air consumption by 30-45 per cent.

The pumps are designed with a minimum of moving parts and all main parts can be changed

without disconnecting the pump.

The patented diaphragm suspension and air valve design of the pump has proven though trials that diaphragm life is generally increased up to five times.

The compact outer measurements and capability to install the pump upside down, sideways or vertically provides excellent flexibility during installation and set up.

• demm.co.nz/reader-enquiry #DW131205

Email ianm@pumpsystems.co.nz