To be competitive in global markets New Zealand manufacturers are applying innovative technologies to deliver products to market faster and cheaper.

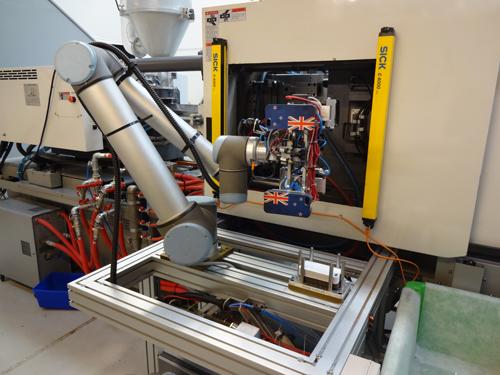

Talbot Technologies deployed two of Universal Robots’ UR10 industrial robot arms to perform in-mould modelling, transfer moulding and co-moulding tasks on the company’s Christchurch production line.

Since the installation of the first UR10 in 2013, the firm has reported increases in productivity, reliability, quality and cost savings.

Talbot Technologies is an integrated technical plastics manufacturer and solution provider that works as a design, development and production partner across a wide range of industries, for companies across the globe.

The firm has been trailing various technologies aimed at providing high quality output at a lower cost. Having been introduced to Universal Robots by Design Energy, the company’s NZ distributor, Talbot Technologies began exploring various application options.

According to Steve Wilson, executive director of Talbot Technologies, the business required a flexible, easy-to-programme, five-axis robot for a specific application.

“We conduct complex in-mould labelling, which has quite a few components, and a fixed rail robot simply doesn’t have the capacity or the versatility to deliver the type of results we need,” says Wildon.

“After extensive discussions with Design Energy, we agreed that the style of robot offered by Universal Robots would best suit our requirements.

“We had looked at other robots. However, the strong ROI combined with its reliability and versatility made the UR10 a more desirable value proposition for us overall.

“Also another important factor in our decision was knowing we had the support of Design Energy who has all the capability of systemising the robot to our particular application.”

In contrast to traditional industrial robots in the market, Universal Robots’ small and lightweight robotic arms are able to work safely alongside staff (subject to a risk assessment). The UR10 robots comply with the ISO standard for collaborative robots never exceeding a force of more than 150 newtons.

The firm’s robots are also equipped with a state-of-the-art “stop-force” safety feature that automatically stops the robot from operating when it is subject to substantial resistance.

The UR10 can be reconfigured and deployed for any number of tasks in a matter of hours. The programming, says its Universal Robots, is intuitive, combining a graphical user interface with a teach function which enables the operator to simply grab the robot arm and show it how a movement should be performed. The user-friendly interface then allows staff to drag and drop the routines to do their programming - this functionality is very similar to an iPad.

Talbot Technologies relied heavily on manual handling of products and in some cases used rail robotic technology. However, due to the company’s rapid growth, Wilson needed to streamline the production process to help drive efficiencies in workflow.

“The UR10s have enabled us to combine functions that occurred off-machine and on-machine and others which happen either prior or post production – helping us to better streamline the process flow,” says Wilson.

“At the moment the main cost reduction is gained through an improvement in quality. We always get exactly the output we want product-wise without repeatability through error – which has provided a solid return on our investment.”

The firm expects to see a full return on investment within 12 months from implementation.

“We are planning on adding additional functions to what the robots currently do, which will make other downstream processes obsolete and provide further return as we go forward,” says Wilson.