Increased uptime, low maintenance costs and work safety are main drivers for the development in heavy industry.

The level of investments in plants are increasing, and production is becoming more efficient with factories produce more product year to year, and equipment cost and the losses in production caused by downtime is consequently increasing.

There is a need to increase the time between repair and improve the ability to predict failure to avoid unplanned downtime. If companies are not successful in doing so it will risk their business.

The Health and safety legislation have finally caught up with people’s expectation on companies work safety. That, in combination with the ongoing discussion about getting home and getting home safe from work, is driving the need for new work procedures and new solutions in the plants. Every time an employee is close to a machine it is seen as a risk of injury, and they’re considerably higher with unplanned maintenance compared to planned, however some risks may be eliminated when maintenance free solutions are used.

Many companies are investing a large portion of their R&D to develop solutions for increased uptime, reduced maintenance and improved work safety. Often it is not just a single product, but complete systems that need to be developed.

One contribution from SKF to increase the performance of rotating equipment is the three-barrier solution for applications in harsh environments. It can be a virtually maintenance free solution that both increases time between repair and reduce the health and safety risk of maintenance.

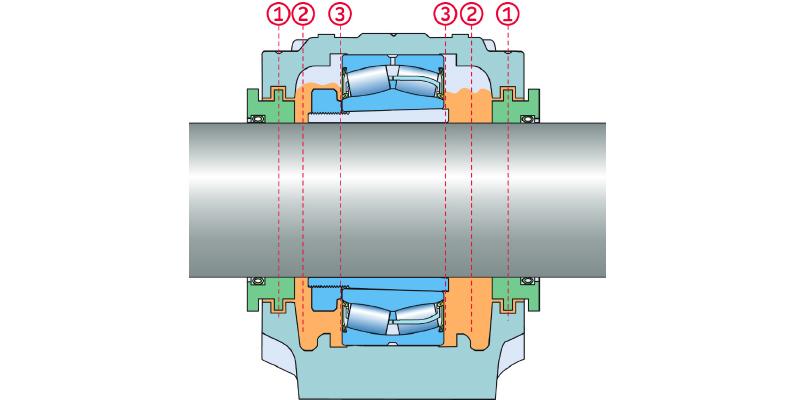

By using a plummer block housing with suitable seals, a sealed spherical roller bearing and filling the housing free volume with grease, the bearing is protected by three barriers that provide exceptional results in excluding contaminants. The arrangement can then be monitored by using temperature and vibration sensors such as SKF’s copperhead sensor that has been specifically designed for the heavy industries such as mining and timber.

Barrier 1 - SKF housing seal

It is common to use a labyrinth seal or the four-lip seal normally fitted to a SNL type plummer block housing. For harsh conditions SKF has also developed a Taconite Seal with a heavy-duty multistage axial labyrinth with v-ring seal and has proven to be effective in extreme environments.

Barrier 2 - Housing grease

The free space in the housing is filled with grease to trap any possible ingress of contamination through the external seal.

Barrier 3 - SKF Explorer sealed spherical roller bearing

By utilising a sealed bearing, ingress of contaminants is not only prevented during operation, but also during installation. The performance enhancements incorporated into sealed spherical roller bearings can best be demonstrated by comparing the calculated bearing life of a sealed spherical roller bearing with a comparable open bearing. With contamination close to zero in the sealed bearing the estimated life is four times the life of an open bearing.

One application where the use of the three-barrier solution has been embraced by the mining industry is with conveyors. All the biggest mining companies use this solution across their global operations in Australia, South Africa, Chile and Brazil.

One customer had severe issues in Australia where they had six months between failures, with two of the most recent failures causing an open fire. Investing in the three-barrier solution that included the Taconite seal and condition monitoring, the site has extended the life to more than two years and they also know if the bearings are failing and therefore avoiding catastrophes like open fire.

For further information, please contact your local SKF Authorised Distributor or email customerservice.nz@skf.com.