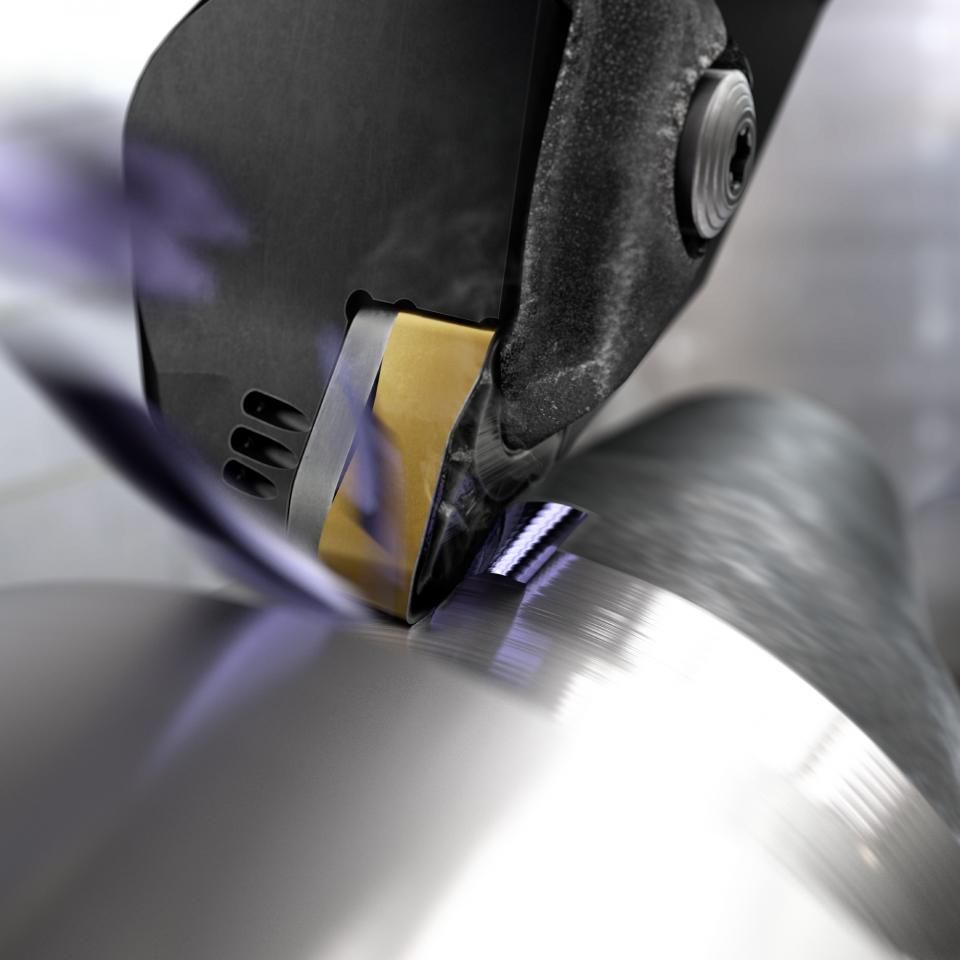

Sandvik Coromant has introduced its second generation of CoroTurn Prime B-type inserts. The new, double-sided negative insert features four cutting edges and is designed for roughing and finishing in steel, stainless and duplex stainless steel, HRSA and titanium.

PrimeTurning has, since its introduction in 2017, aptly been called the biggest innovation in turning, since turning. The method enables turning in all directions and is a productive and efficient alternative to conventional machining.

The concept is comprised of the PrimeTurning method, CoroTurn Prime A- and B-type tools and the CoroPlus Tool Path for PrimeTurning software.

The second generation CoroTurn Prime B-type tools have undergone a major upgrade. “We are continuously working on developing our PrimeTurning offer,” says Staffan Lundström, Product Manager at Sandvik Coromant. “The new B-type tools are improved in all aspects to further support all-directional turning.”

. A key benefit is that the new insert is negative and double-sided. Four cutting edges — twice the edges compared to the previous insert — allow more cost-efficient machining. The tool is also equipped with a new robust tip seat design, which prevents tool breakage if the insert breaks and enables shifting feed directions without insert movements. Furthermore, the geometries are updated for better chip control even in very challenging materials, such as duplex stainless steel and ductile steels.