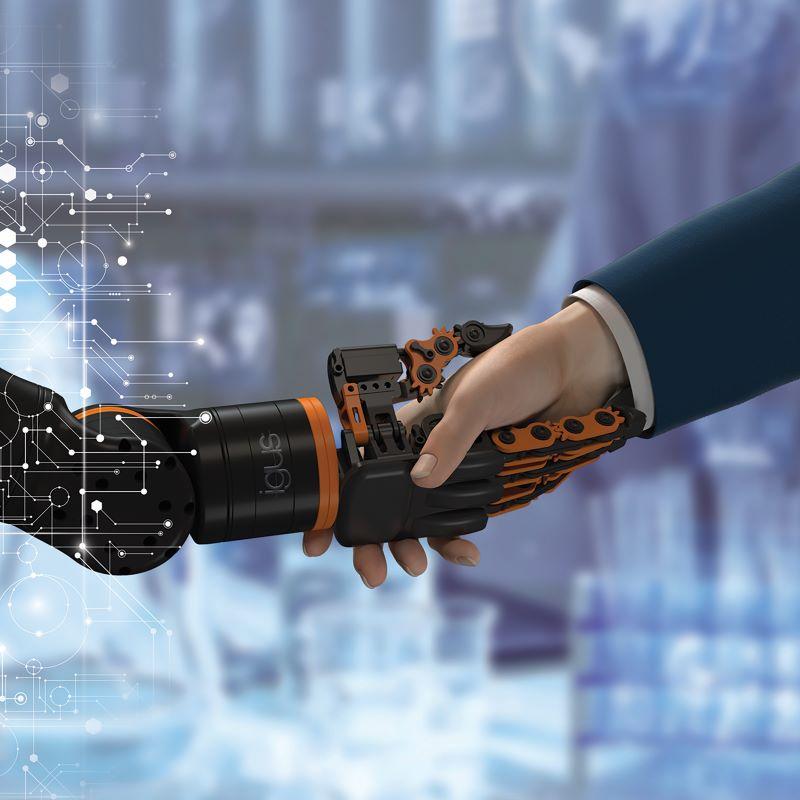

igus adds a humanoid hand made of lubrication-free high-performance plastics to its ReBeL product range.

Robots have become an integral part of industry and are increasingly finding their way into small and medium-sized companies in the form of cobots, such as the ReBeL. They sort, pick and move with the help of cameras, suction devices and gripper systems. igus has now developed a finger gripper for the ReBeL cobot so that it can also perform humanoid tasks. It is made entirely of lubrication-free plastics, and is therefore very cost-effective and easy to integrate.

With the ReBeL, igus has brought a compact and lightweight cobot onto the market, which allows for a cost-effective way to start working with robotics. It is ideal for assembly tasks, quality inspections and jobs in the service sector. So that the robot can actually perform tasks, it requires grippers and suction devices. For this purpose, igus offers a wide selection of suitable end effectors from various manufacturers on the RBTX.com marketplace. "As the ReBeL is very light and inexpensive with a weight of around 8 kilogrammes and a price starting at €3,970, it is often used in humanoid applications. For this reason, we have received several customer requests for a robot hand that can be easily connected to the ReBeL via plug and play," explains Alexander Mühlens, Head of the Low Cost Automation Business Unit at igus GmbH. This is why igus has now developed a particularly cost-effective ReBeL finger gripper, which is available for as little as €1,840. The humanoid hand is compatible with all ReBeL models. It is controlled via DIO at the tool centre point, making it easy to integrate and suitable for various applications. The special feature of the finger gripper is that it can imitate a person's hand movements. "The ReBeL can take on a wide range of simple humanoid tasks and applications with the new low-cost hand. We are thinking of such fields as research and development at universities as well as tasks in the catering or entertainment industries," says Mühlens.

Precise movements thanks to high-performance plastics

All components, including the flange, cables and control unit, are provided directly from igus in Cologne. This gives the customer a solution that is 100% compatible. Lubrication-free high-performance plastics keep the price low. The plain bearings in the joints made of iglidur polymers are not only cost-effective and lubrication-free, but also ensure smooth and precise movements of the individual fingers. Extensive tests in the company's own 3,800-square-metre laboratory guarantee the longevity of the humanoid hand. They are extremely flexible and can be controlled via various interfaces, including USB, TTL (5V) serial and internal scripting. In addition to the finger gripper, igus offers other products for the ReBeL environment. These include, for example, fire-resistant smoke hoods, a 7th axis, gripper sets, adapter plate sets, energy supply systems, a finished workstation and connection cables.

Visit www.treotham.com.au.