Necessity, they say, is the mother of invention. And that just about sums up why an Auckland firm is now tapping into a multimillion dollar industry – making shock absorbers for crutches.

Marshall Basham, director of Auckland Mobility Devices, was playing polo in Kenya when he came off the horse he was riding. The accident left him having to rely on crutches. Back in Auckland, and unhappy about the strain crutches were putting on his body, he decided that installing shock absorbers into his crutches would reduce the pain. Marshall approached John Fowler, managing director of Medical Plastics, a spin-off from John’s manufacturing firm Monaghan Plastics.

They formed a joint venture to fund the design, R&D, manufacture and distribution of what is now known as CrutchShocks.

John says diversifying into premium plastic products was a natural move for his company.

“It has been getting hard to make a dollar out from low grade products, because of the cheap plastic imports from Asia,” he says. “So we are aiming at the emerging New Zealand innovation market. Manufacturing might be in decline here but we can ride the wave of success to get products onto the world stage.”

Medical Plastics is a commercial R&D company, but its sister company manufactures [under contract] surface testing swabs for use in the medical and food industries, as well as animal care products.

“Medical Plastics is a service provider to brand owners, but the CrutchShocks product is something we have partnered in to develop and make – CrutchShocks is essentially our first product.”

John says the production version of today’s CrutchShocks is 30 steps removed from the original concept.

Testing was carried out at the bio-mechanic’s lab at Auckland University, trials included using a mechanical testing machine as well as with users of crutches modified with a prototype shock absorber.

Funding for the project was provided by John and Marshall, and there was some help by way of a government grant – although John says obtaining grants is a slow process that delayed getting the product completed.

“R&D is often a torturous path to market,” says John. “It is a process of elimination, a process of testing and getting opinions from a wide range of sources. It’s good to share ideas with someone who is impartial, and then it’s back to the drawing board.”

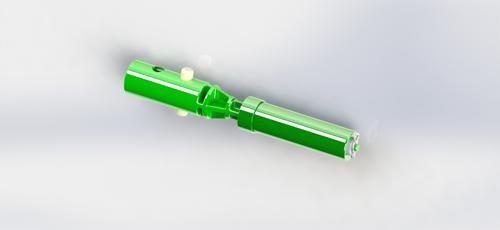

The CrutchShocks feature a steel spring inside a robust plastic housing, made by John’s firm. The device slots between the two sections of modern metal crutches, providing the user with a shock absorber that reduces the impact of the crutch hitting the ground by up to 20 per cent.

“It’s not like the front shock of a mountain bike,” says John. “You can’t have four inches of travel because that would be unnatural. Instead, the CrutchShocks provides for 5mm of travel – it feels perfectly natural.

“The CrutchShocks provides rapid deceleration down to stop, whereas a normal crutch is just solid. With an unmodified crutch the impact goes right through to your shoulder, whereas placing 5mm of movement into the crutch means the initial peak of pressure is dampened.

“That impact shock of walking with crutches can be brutal, and can lead to secondary injuries such as nerve damage as well as strained joints and ligaments. Whereas if you put a shock absorber in there then the shock is reduced.”

Among the first users of the CrutchShocks was Olympic gold medal shot put champion Valerie Adams. She used CrutchShocks for a week following surgery last year.

“She was really pleased with them,” says John. “She could instantly see the benefit and loved the idea.”

The CrutchShocks will sell for around $20 (US$15) a pair.