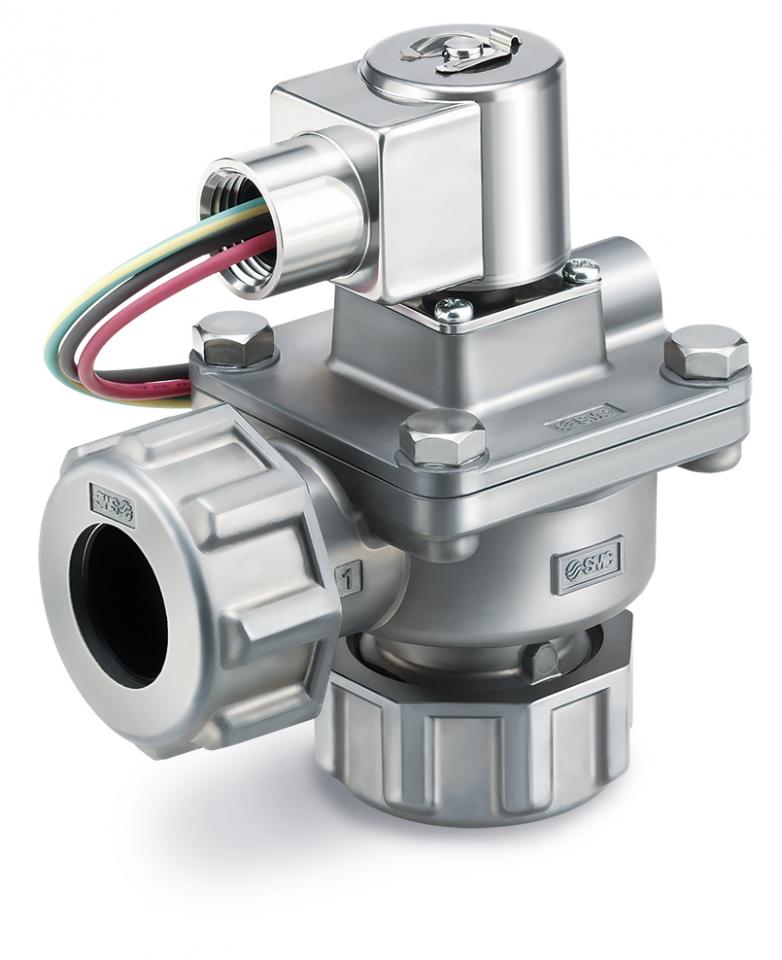

SMC Corporation recently introduced a solenoid operated option to the company’s extensive valve range. It acts as a high peak pressure and fast closing pulse valve, specifically designed to reduce air consumption in pulse blowing applications.

Designed with productivity in mind, the JSXF series is ideal for use in filtration collection systems where a reliable and robust valve solution is required to clean filtered particles off any type of bag filter. SMC’s springless diaphragm construction ensures a longer and more reliable valve life whilst operating at peak efficiencies.

SMC’s new solenoid design ensures improved environmental resistance with a stainless-steel cover (IP67 enclosure) for the magnet wire of the coil part. The M12 connection for the coil is now available, and 360º lead wire entry enables easy lead wire handling. Moreover, coil replacement is made simple.

Darshan Desai, Product Specialist for SMC Corporation Australia New Zealand (ANZ) explains that the valve has been introduced at the right time: “Australia and New Zealand’s environmental guidelines now requires that companies monitor and assess dust management programs across many industrial applications - from grain and timber mills to cement handling, metals and mineral processing. We recently carried out a project at industry pioneers, GRAINTECH Engineering where we retrofitted solutions to suit their plant - allowing for better control whilst improving air pollution and emissions. The same can be done for all SMC customers.”

The increased efficiency of the air pulse action is achieved thanks to its high peak pressure, while low air consumption supports environmental targets. “This range has been developed with a strong focus on air efficiencies. Our company is dedicated to achieving our Sustainable Development Goals (SDGs) and this range once again underpins our commitment to sustainable manufacturing.”

With a long service life of 10 million cycles, springless diaphragm and compression fitting, customers can enjoy cost, maintenance and installation savings. “In addition, the JSXF is robust and adaptable to different working conditions - managing high flow rates and a range of fluid temperatures from -40 to 60 ºC.”

GRAINTECH were part of the initial JSXF pilot project on local shores. “GRAINTECH introduced in-house bag houses to complete their turnkey offering and reached out to SMC to assist with their automation requirements. We saw this as the perfect project for the JSXF on local shores and partnered with them to further explore its technical capabilities and undertake in product testing. The client was really impressed with the results and continues to use the JSXF range (in the air operated version).”

Darshan concludes saying: “We are constantly seeking ways to support our customers with solutions that will help them to remain competitive in a global marketplace. The JSXF series is a small but significant valve solution that completes our range of offerings in terms of operational and environmental objectives.”