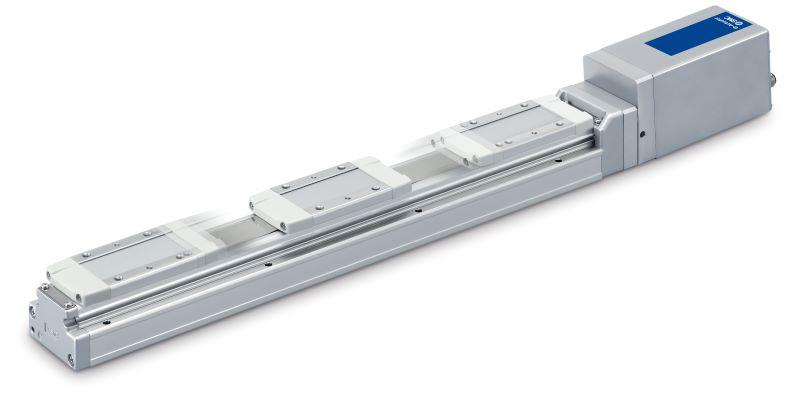

SMC’s latest electric actuator series, the EQ series of slide-type and rod-type actuators, feature a fully integrated controller, providing a simpler to set-up, easier-to-use, space-saving solution that simultaneously helps customers save energy, all while reducing CO2 emissions.

Delivering the benefits that customers have come to expect from SMC’s electric actuators, the EQFS (slide type) and EQY (rod type) electric actuators are designed to overcome automation project challenges such as labour-intensive wiring, downsizing control cabinet space, reduce power demand and eliminate time consuming programming and commissioning.

“The EQ series is ideal for a whole host of applications, including transfer, assembly, lifting, dispensing, pressing and clamping. It is ideal for use in any automatic process where a higher degree of precision or control is required or where compressed air is not available,” says Jozef Ceh, Group Manager ANZ Integrated Solutions for SMC.

Another key benefit comes in the form of the exclusive free configuration software on offer, as Jozef explains: “Customers can set up the actuator via a single screen in just three easy steps.”

Customers will opt for ‘set up operation mode’ before specifying the stopping positions and finally defining the speed, acceleration and deceleration by entering numerical values into the specific fields or by cycle time.

“It is no more complex than controlling a two- or three-position solenoid valve, making it an easy to integrate solution.”

Save space & reduce cabling

Notably, the electric actuator and controller are part of the same product - saving on wiring time and space. “This simplified configuration, alongside, the use of only two connectors, also eases set-up and facilitates immediate use,” adds Jozef.

The series includes an optimised motor specification, updated control method and improved rotational efficiency, resulting in reduced heat generation from the motor and lower power consumption. “Depending on the operating conditions, it is also possible to reduce emissions by up to 60% compared with existing solutions.”

Easy to retrofit

To simplify retrofit applications, the EQ series has the same mounting dimensions as the SMC LEFS or LEY standard electric actuator series, making for easy replacement.

“All EQ series e-cylinders already come standard fitted with an Absolute Encoder system, but if further external sensing is required, they are compatible with standard SMC D-M9 series auto switches, for additional sensing over the entire stroke,” notes Jozef.

Jozef concludes saying that customers from a variety of industries requiring speed, accuracy, control or simply quieter and more energy efficient machines stand to gain from the latest addition to the company’s portfolio.