Emerson says it has improved AMS Machinery Manager predictive maintenance and analysis software with new visibility tools and mobile access to help users more quickly identify and act on machinery health issues anytime and anywhere. New integration between AMS Machinery Manager and the Plantweb Optics asset performance platform enables automated workflows – helping maintenance and operations teams focus on exceptions to make better decisions faster.

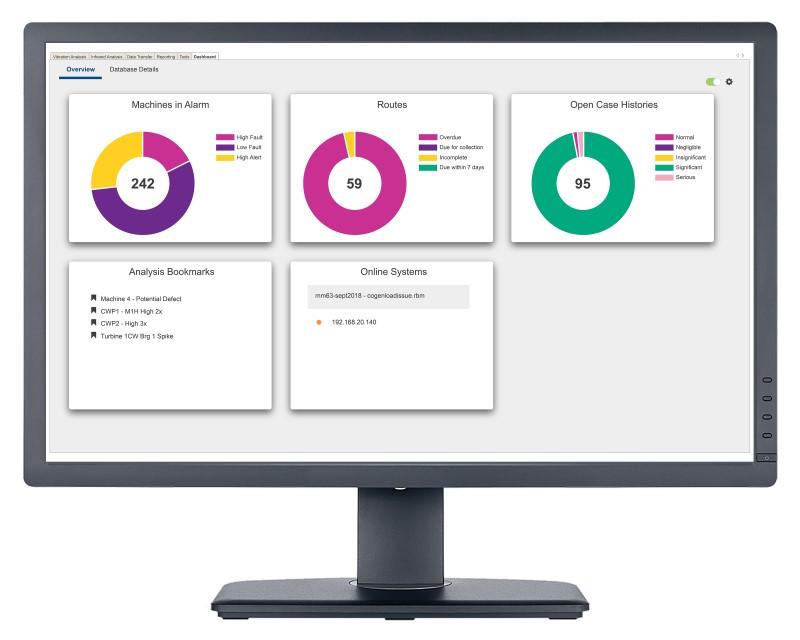

The number of devices and sensors that organisations employ to ensure continuous, safe operation has grown significantly. When data from these devices is unprioritised, it can obscure problems, making it hard for operators to quickly determine pressing issues, says the software developer. A new AMS Machinery Manager dashboard helps solve this challenge by automatically filtering critical data and passing it to users’ mobile devices via Plantweb Optics. With instant mobile alerts, users can more quickly identify and analyse machines with potential defects.

The AMS Machinery Manager dashboard is also more interactive, says Emerson, allowing users to delve in and quickly discover root causes for asset alarms. Users can click on problem assets to drill down to health data with analytics tools – such as Emerson’s PeakVue technology for early indication of equipment defect development – to receive a clear indicator of overall asset health. A new analysis bookmarks feature helps users easily monitor critical issues. Upon identifying an alert or status that needs further review or action, users can flag items for second opinions or as a reminder to take action or revisit specific assets.

“Today’s manufacturing leaders know that it is essential to get machine health data to the right people quickly, no matter where they are,” said Sean Key, product manager for AMS Machinery Manager. “Plantweb Optics integration allows AMS Machinery Manager to deliver that targeted data to mobile devices to help build proactive, automated workflows – speeding response times and helping reduce downtime and improve operations.”

Plants depend on regular maintenance routes to ensure equipment performs properly. Often, ensuring these routes have been completed promptly and properly means creating and analysing detailed reports. AMS Machinery Manger now simplifies route management by making detailed information available on the operator dashboard in human-centred graphic displays. Users can identify overdue or incomplete routes at a glance – without the need to run a report.

AMS Machinery Manager and Plantweb Optics are part of the Plantweb digital ecosystem, which equips plant operators and technicians with new insight into the health and performance of their assets and processes to help them shift from a reactive maintenance culture to a proactive approach that results in less downtime and lower maintenance costs.

AMS Machinery Manager can now be installed on-prem or in the Cloud, reducing the need for on-site information technology to manage software installations. Emerson has also expanded the AMS Machinery Manager database to support up to 32GB, helping users consolidate all their asset data into a single installation.

Software upgrades speed predictive maintenance response

Maintenance Matters

Tuesday, 06 August 2019