Skyrocketing energy prices, dwindling fossil-based energy resources and increasing competitive pressure motivate politics and society to fundamentally reconsider the way we deal with energy. Legal guidelines and regulations lend further impetus. Numerous investigations and studies show that, in many cases, there is a considerable savings potential of up to 30 percent and more. Energy management systems based on the ISO 50001 help tap this huge potential.

ISO 50001 Energy management systems – Requirements with guidance for use, is a voluntary international standard developed by ISO (International Organisation for Standardisation). This standard establishes a framework for industrial plants, commercial, institutional, and governmental facilities and entire organisations to manage energy. Targeting broad applicability across national economic sectors, it has been estimated that the standard could influence up to 60 percent of the world’s energy use.

The general aim of this standard is to support organisations in the set-up of systems and processes to improve their energy efficiency. Systematic energy management leads to the reduction of energy expenditure, energy costs and greenhouse gas emissions. An energy management system (EMS) determines the energy situation in the organisation; helps redefine the energy policy of a company based on concrete data and improves the energy efficiency. Furthermore, factors that influence energy consumption must be identified in order to continuously monitor and measure them. The energy manager of a company is responsible for pursuing the defined goals and continually improving the results achieved.

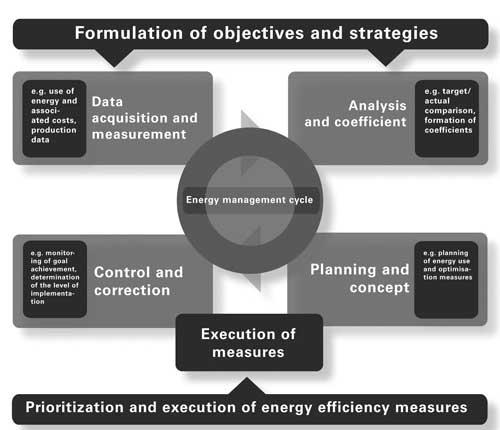

The decisive component in an energy management system is an effective and continuous energy controlling control circuit. A control circuit of this type consists of four stages: data acquisition, energy analysis, energy efficiency measures and inspection.

Continuous data acquisition

A first step to escape the financial trap is the precise acquisition of all energy data, electrical and power quality parameters. First of all, the operating, consumption, and cost data (e.g. power, gas and district heating invoices) must be acquired and recorded by qualified personnel during the data acquisition phase. To make a detailed evaluation of an organisation and to create a basis for relevant energy efficiency measures, the energy flows must be further resolved from the supply side all the way down, which means major consumers or company units must also be measured and sub-measuring points are required.

Because larger companies have many measuring points, often even hundreds of measuring points, automatic acquisition of the energy consumers must be provided. Significant points for the configuration of such a data acquisition system include the decision about the data required (which electrical and energy parameters), data resolution (different data requires different averaging times), query intervals and the communication architecture (e.g. TCP/IP (Ethernet), Bacnet, Profibus, Modbus …). Modern energy measuring technology provides the necessary transparency in the field of building energy supply. Continuous data acquisition is recommended in order to react speedily to changes in operation while also documenting the results achieved.

Via corresponding communication architectures, the acquired data is transmitted to a central location, stored centrally in high-performance databases and made available for further processing in an architecture that is as open as possible. Attention must also be paid to simple integration in higher-level systems, e.g. SCADA systems, building control technology or PLCs, as appropriate.

Energy analysis

The energy analysis is based on the data of the automatic measurement data acquisition system. The energy analysis provides the basis for the concrete goals of the enterprise with regard to energy consumption and energy cost reduction (e.g. 10 percent energy savings a year). In addition, the energy analysis results are also the significant starting point for an ABC analysis of the loads, the development of a catalogue of measures, evaluation of specific measures, prioritisation of the energy efficiency measures and creation of a detailed plan of measures.

Planning of measures

The results of the energy analysis flow into the planning of measures for reducing the energy consumption and energy costs. The measures can be divided into four groups:

Planning: Examination of energy use, optimisation of operating times, machines with high efficiency, peak load optimisation, heat recovery, etc.

Organisational measures: Area of acquisition (e.g. putting emphasis on the life cycle costs), changes to the workflow, in the area of regulation/control, the conduct of employees, during maintenance and repair, training and motivation.

Technical measures: Use of more energy efficient motors (more than 95 percent of the life cycle costs of an electrical drive are energy costs), changing to frequency inverters, use of heat recovery, leakage reduction in the compressed air network, optimisation of the regulation and control of systems, optimisation of steam generation, intelligent use of peak load optimisation/energy storage etc.

Load management: Load (peak demand) management constitutes a special measure. Optimisation of the power load profile does not primarily bring energy savings but, depending on the power supplier contract, leads to substantial cost savings. This measure also stabilises the energy supply.

Checking and correction

After integration of an energy management system in the company, it is important to rigorously continue and further develop it. In other words, an EMS is not a unique or short-term project, but a continuous process. It is important to repeatedly check that the set goals have been achieved and to introduce improvements where necessary. The goals must also be inspected at regular intervals to check that they are still sufficient and updated if need be. Only with automatic data acquisition can goals – both achieved and future – be discussed and redefined on the basis of the relevant data. Or else the comparison (e.g. with the previous month) indicates trends (e.g. capacity utilisation of the operation) and identifies errors in time (e.g. leaks in the compressed air, mains feedback effects causing high neutral conductor currents or even posing a fire risk).

Energy efficiency measures can be monitored and documented after implementation of automatic data acquisition, comprising all kind of energies, such as heat meters, gas meters, network analysers and multi-function measuring devices, for example.

Benefits of an EMS

• Identification of ‘energy wasters’ and introduction of measures results in the reduction of power and energy costs (kWh, peak load costs, reactive power costs).

• Reduction of climate killing carbon dioxide (Green IT, Zero carbon offices, Kyoto etc.).

• Stabilisation of processes (improvement of the power quality).

• Lowering maintenance costs by pro-active maintenance and reduced stress factors.

• Avoiding power failures, e.g. due to harmonic currents or resonance problems, voltage sags or transients.

• Raising awareness of employees with regard to energy savings and climate protection.

• Fulfilment of legal framework guidelines, energy tax reduction.

• Cost centre management enables consumption-oriented cost allocation.

• Cultivation of environmental protection and corporate image.

The power bill is usually the gauge for the cost calculation of operational plants, buildings or infrastructural facilities. However, this bill is only the visible part of sometimes much higher costs, taking a ‘dirty’ and unreliable energy supply into account. Next to the direct electricity costs, the effective capacity utilisation of energy distribution systems and facilities as well as a reliable energy supply also play an important role in economic efficiency. As these costs are not so obvious, they are also referred to as ‘hidden costs’.

With an integrated, integral energy management system, you can also centrally monitor and compare (benchmark) branches at various geographical locations, for example. The power consumption, reactive power monitoring, water and gas consumption, the availability of electrical energy and the power quality can be collected, evaluated and analysed in the company headquarters’ database. This can also increase energy efficiency as saving potentials are revealed by cost comparison.

Practically at the push of a button, the relevant software can be used to prepare the various data and create statistics and tables in the desired format, which are then made available to the financial controller, the energy manager, the purchasing department or facility management. In the area of property management, this also means an improvement of the preciseness of power consumption accounts and convenient, automated, customer-specific accounting (cost centre management), for example.

End-to-end energy management systems create network transparency on the various network levels, which allows the identification of possible ‘sinners’, uncovering inefficient processes and initiation of corresponding energy efficiency measures. Many energy efficiency measures can be achieved with low financial investments. And even with real capital investment, a return of investment can often be expected within six to 18 months.

ECCA funding

Would you like to reduce your energy use and costs while building your brand? If you would like to improve your building’s energy use but haven’t got the capital, a Commercial Project Grant from EECA could fund up to 40 percent of the cost to help your project ‘over the line’. Commercial project grants may be used for:

• Upgrading or replacing equipment e.g. lighting, refrigeration, heating and air conditioning.

• Continuous commissioning systems that adjust energy use in line with demand.

• Monitoring and targeting systems that monitor energy use and target areas for improvement.

Article by Michael Welzel, Direct Control Ltd. The Auckland based company is one of the Programme Partners of ECCA and supports the ISO 50001 with integrated building automation and energy management solutions.

Email: mwelzel@directcontrol.co.nz