With NXD, Nord Driveystems has launched the latest generation of its surface treatment. The system manufacturer equips its aluminium drive solutions with two variants of effective surface protection. This makes them more resistant to extreme environmental conditions, and ensures longlasting performance even under demanding operating conditions.

NXD is the surface treatment from Nord for gear units, smooth motors and frequency inverters made from aluminium. It provides the users with an economic and effective alternative for the surface protection of drive solutions, which are heavily stressed by extreme environmental conditions. With NXD, Nord increases the durability of these drive systems and thus prolongs the system availability. The surfaces are free from chromates and PFAS.

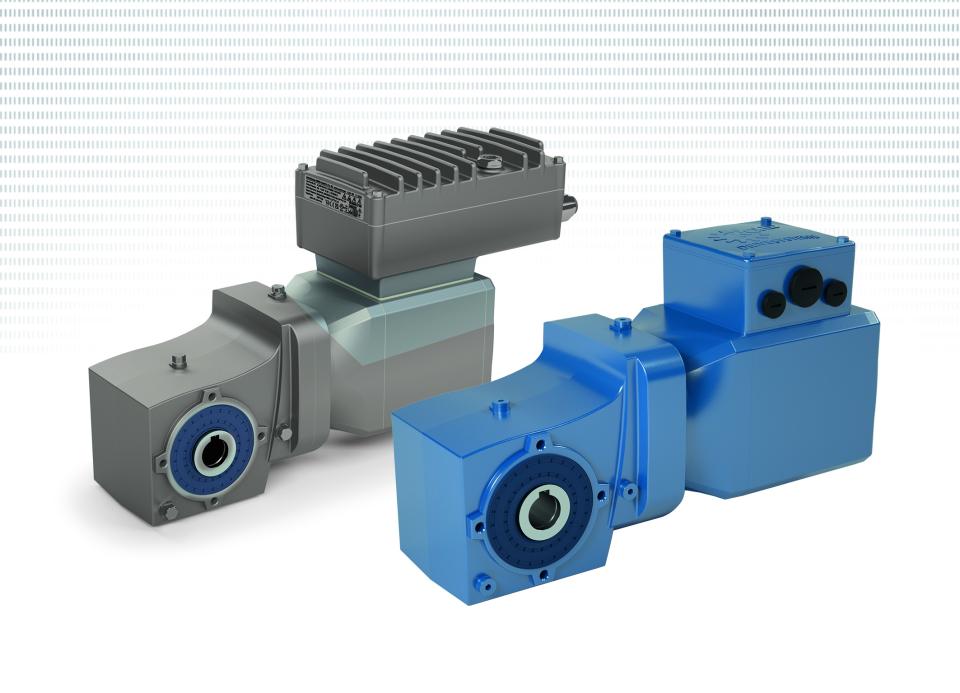

Two variants for perfect and effective protection

With NXD, aluminium surfaces are galvanised, making them particularly corrosion-resistant and durable. The latest generation of surface protection is available in two variants. NXD BASIC consists of the galvanically produced base layer with an additional varnish. Corrosion protection is also ensured in case of damage to the varnish. The variant is suitable for use under demanding environmental conditions such as offshore areas.

The second variant is the food-safe NXD tupH. Here, this galvanised base layer is treated with a sealer. This process prevents flaking or microcracks prone to germs.

Food-safe drive systems with NXD tupH

NXD tupH offers safe surface protection for extreme conditions in wash-down applications. It makes drive solutions resistant to acids and alkalis from the regular cleaning and disinfection processes. Even if damage occurs to the galvanised base layer, no particles will flake off due to the sealing, which makes NXD tupH surfaces hygiene-friendly and thus suitable for use in hygienically critical industries.

NXD tupH is food-safe according to FDA and according to EU Regulation 1935/2004. This makes components with an NXD tupH surface suitable for the processing of hygienically sensitive products in almost every important market worldwide.

Aluminium offers numerous advantages

With NXD, Nord reveals the advantages of aluminium for demanding environments and hygienically sensitive production areas. Aluminium is lightweight, economical and fully recyclable. Furthermore, aluminium housings provide better heat conductivity, thus reducing their maximum surface temperature.

NXD is available for all Nord drive components made of aluminium, including the integrated DuoDrive geared motor system, the energy-efficient IE5+ smooth motors as well as NORDBLOC.1 helical in-line gear units and NORDBLOC.1 bevel gear units. With the NORDAC ON PURE, a decentralised frequency inverter with an NXD tupH interface will also be available soon. The solution provider can thus supply complete drive systems with food-safe surface treatment from a single source.

https://www.nord.com/en/home-uk.jsp

https://www.nord.com/en/products/additional-topics/corrosion-protection/nxd/nxd-basic-nxd-tuph.jsp