Process automation firm Festo’s safety concept covers not only motors and controllers but axis mechanics.

“While the subject of machine safety is not new, it will continue to play a key role in machine and plant construction,” says Fredrik Stal, the firm’s head of product management electric drives.

“In applications that are not protected by safety guards, but where people can come into direct contact with plant components, all electromechanical systems must have integrated safety functions to guarantee adequate risk reduction.

“Users must be offered an overall safety concept, which supports monitoring of the axis mechanics as well as safety-related clamping or braking.”

Stal says that in the past, operators sometimes had to make do with a retrofitted safety concept. Many would take any safety switching device and wire the STO function. They also replaced the servo motor with a motor with a brake.

“Many machine manufacturers think that this is enough,” he says. “However, this does not take all possible errors into account, as a coupling assembly error or a cracked toothed belt in the reversing unit could render the brake useless.

“These errors would cause the slide unit and the load to fall, causing serious injury. Furthermore, undetected bearing damage could stretch the toothed belt or damage to the recirculating ball bearing guide could cause the axis to drop by several millimetres after a crash. The slide could therefore cause crushing.”

Stal believes a fully integrated solution monitors the axis mechanics and allows safety-related clamping or braking.

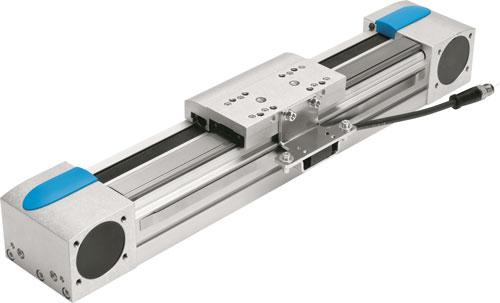

“This is exactly what the safety-related electric axis EGC with dual-channel displacement encoder and clamping unit from Festo does,” he says.

“The mechanical system can be monitored by a motor encoder (first channel) and a linear displacement encoder (second channel).”

Stal says these drive-related safety functions can be monitored by the certified safety system CMGA for motor controllers. Conventional safety command devices such as emergency stop switches, protective door switches, light curtains and laser scanners can be connected to the system.

As soon as these trigger a safety requirement, a safety-related stop such as an SS1 or SS2 is triggered via the safety system CMGA or safely limited speed is monitored in set-up mode. For ease of use, there are pre-validated application programs for many machines. These reduce the complexity of a programmable safety system to the simplicity of a safety relay.

Go to www.demm.co.nz/enquiry and quote DW130326a