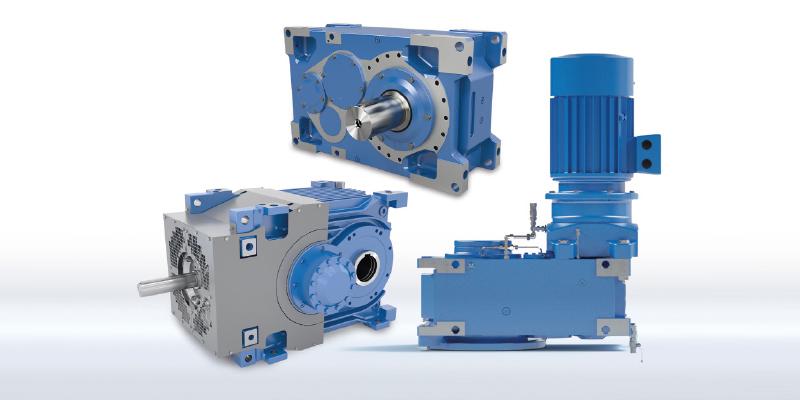

NORD DRIVESYSTEMS has added the new MAXXDRIVE XT series with right-angle gear units and a thermally optimised design in seven sizes from 15 to 75 kNm to its overall portfolio of parallel and right-angle gear units. The modular system allows for the planning of perfectly matched drive systems for heavy-duty applications like conveyors or agitators, promises drive technology solution provider.

MAXXDRIVE industrial gear units are used when high output torques and powers are required and in combination with the suitable accessories, provide a ‘technically and economically perfect’ drive solution for each customer project. The company says the comprehensive configuration and mounting options allow for standardised, as well as tailor-made, drive solutions. The combination of motor, gear unit, coupling and braking system, for example, results in precisely planned complete units that are supplied ready-to-install, mounted on a motor swing base or a base frame. As an alternative, the motor attachment can be realised via an IEC/NEMA adapter. A large variation of available flange and output shaft versions ensures that the customer’s application is ideally matched, states NORD. The mechanical and thermal design of all NORD industrial gear units is always based on the existing operating data of the application and on the ambient conditions at the installation site. Therefore, says NORD, the MAXXDRIVE portfolio ensures maximum individualisation, creating drive systems that fulfil the highest demands in terms of reliability and long service life.

Variety of options for tailor-made application concepts

Typical MAXXDRIVE applications are drives for conveyor belts, consisting of an electric motor, a coupling solution and an industrial gear unit with axial fan. The primary focus here is on a sufficient heat dissipation to allow for ultimate thermal limit powers. The new MAXXDRIVE XT industrial gear units with their heavily ribbed housings are ideally suited for this purpose, states NORD. The power and speed ranges of the application-optimised 1/3 two-stage right-angle gear units have been specially designed for applications in which low speed ranges are required in combination with high powers. MAXXDRIVE XT series output torques range between 15 and 75 kNm with speed ratios of 6.3 to 22.4. MAXXDRIVE XT industrial gear units are available in seven sizes for powers from 50 to

1,500 kW.

Another typical application for this strong range of industrial gear units includes drives for mixing and agitation processes. By equipping the compact and robust MAXXDRIVE industrial gear unit with reinforced bearing and flange versions (VL2/KL2 – VL6/KL6), the drive can be optimally adjusted to application loads. Sealless IEC/NEMA adapters (SAFOMI) and a TRUE DRYWELL sealing at the output shaft allow for highest possible operational reliability. The entire drive system – from NORD electric motors to flange connections – is delivered as a ready-to-install unit, which can easily be mounted vertically on the application.

Networked maintenance concepts

NORD also offers innovative predictive maintenance concepts specially designed for MAXXDRIVE industrial gear units. The NORD frequency inverter is an essential component here. The status data available in the inverter can be communicated to a higher-level control or directly to a safe cloud. The inverter can also directly record external sensor data for vibration monitoring or for measuring the gear unit’s oil sump temperature. Changes to the system condition can be detected at an early stage (condition monitoring) and predictive maintenance can be scheduled in good time.