Businesses could reduce boiler running costs by up to 25 percent with help from an Energy Efficiency Conservation Authority (EECA) programme.

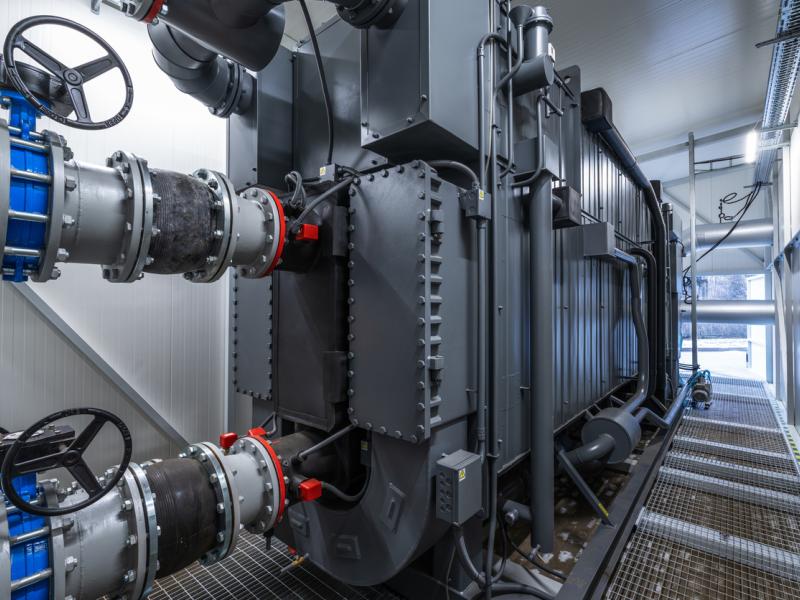

The EECA Boiler Tuning Programme can help users of large steam and hot water boilers, such as factories and hospitals, to optimise the fuel use of their boilers.

Funding of up to 40 percent of the cost of six-monthly boiler tunings for two years is available to companies in the scheme.

EECA Business project manager Pramesh Maharaj says: “One industrial site we worked with made cost savings of $45,000 a year from a boiler tuning. It took only a couple of hours to complete and started delivering to their bottom line immediately.”

Research carried out by EECA shows the long-term business benefits of regular boiler tuning are not well understood.

“Typically boilers are tuned only when there is a disruption to the steam or hot water supply. For optimal performance boilers should be tuned once every six months,” says Maharaj.

“The aim of the programme is to raise awareness of the business benefits of boiler tuning and encourage businesses to put in place a regular programme for boiler tuning services.”

The boiler tunings are being done by firms such as RCR Energy, Energy Plant Solutions, Gas and Oil Combustion Services, and Advanced Boiler Services.

A spokesman for Advanced Boiler Services says that on a steam boiler, an economiser can improve its efficiency by 6ºC or more, depending on the exhaust gas temperature and size of the boiler.

“These are normally only fitted to boilers with modulating feed water control valves to ensure water flow through the economizer, but on smaller boilers a closed system can be used circulating into the feed tank,” he says.

Another option is to pre-heat the water, using steam injection to heat the tank of feed water.

“A heat exchanger is a very energy efficient way to heat the feed water but is dependant on the condensate return rates,” says the spokesman. “A rise of 6ºC in boiler water temperature by condensate return can produce a fuel saving of 1 percent.”

He also says that any leaks in process equipment and pipe work is lost energy, requiring the replacement of water, more energy to heat that water and chemicals to maintain a balanced water system.

“Leaking valves and glands is a very common cause for the loss of steam and easily remedied by servicing valves regularly and replacing gland packing to ensure valve spindles are not damaged through erosion,” he says.

“Exposed pipe work and equipment can reduce the temperature of the heating medium and therefore more energy is required to prevent heat losses required to operate equipment. It is a good idea to insulating pipe work.

“Also, by ensuring that all condensate traps within the process are well serviced and operating correctly will ensure that steam is not lost returning back to the feed tank or going to drain.

“Most condensate traps can be checked with an instrument without removing the traps from the system and this should be done at periodic intervals.”

Contact kmalpas@absboiler.co.nz for more information.