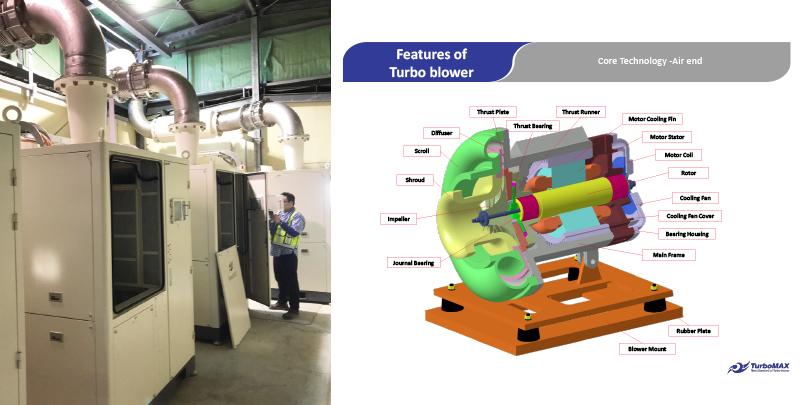

There is a new type of turbo blower making a name for itself in town – TurboMAX. TurboMAX is operational on 3000 sites around the world including New Zealand. The TurboMAX turbo blower is a product that provides the best efficiency through the use of a high-speed motor, air foil bearings, and a powerful centrifugal compressor design, promises the manufacturer. The company says the TurboMAX blower will reduce energy costs by more than 30 percent compared to traditional blower designs and provide a clean and quiet working environment, along with many other benefits. The Turbo Blower, a system used to produce compressed air, is directly connected to permanent magnet, synchronous motor which is operated by an inverter. The product is a single stage, centrifugal type Turbo Blower which consists of air bearings, an impeller, a high-speed motor, an inverter, a controller, and a cooling system.

It has a myriad of advantages. These include:

ENERGY SAVING

• Reduces energy consumption by 20-40 percent ‘compared to existing products’

• Recoup initial investment in a short period of time: ‘two to three years’.

• Designed to operate at high speed with high efficiency.

USER FRIENDLY

• Convenient user interface is used.

• Provides automatic operation mode that is required on-site.

• Reduced noise (less than 85dB), no-vibration.

• Oil free lubricating system.

SIMPLE MAINTENANCE AND EASY INSTALLATION

• Only regular inlet filter replacement is required.

• Automatically detects errors and takes necessary actions.

• Special expensive foundations and anchor work are not required because TurboMAX blowers have no vibration.

• Time required to install the product is minimised.

NU-WAY IS THE DISTRIBUTER FOR TURBOMAX IN NEW ZEALAND AND AUSTRALIA