Inventory management software company, Unleashed, has released a new product giving smaller manufacturers the Material Requirements Planning (MRP) abilities of companies many times their size – at a fraction of the price.

Very high implementation costs as well as technical complexity typically prevent small businesses from accessing enterprise MRP systems, limiting their ability to efficiently replenish raw materials.

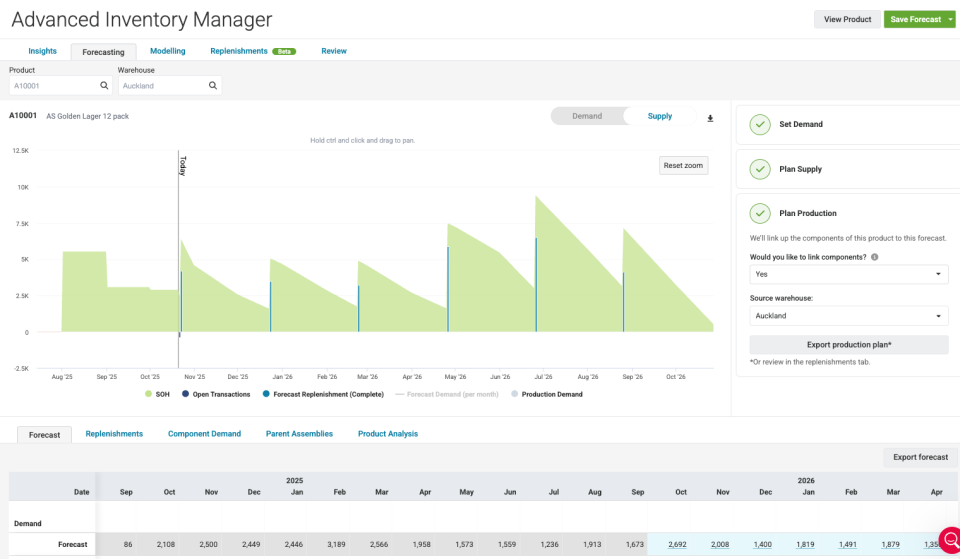

Recognising this need in its user base, Unleashed – a cloud-based inventory, purchasing, sales and production platform popular with small & micro manufacturers – has evolved its existing demand forecasting module, AIM, into a simplified MRP.

The flagship amongst a raft of new features for manufacturers, the tool can now connect thousands of product-level demand forecasts into the raw material purchasing plans – and assembly schedules – needed to meet them.

“At just $150 a month, this gives even very small manufacturers the ability to manage complex production and purchasing without big costs or extra staff,” says Unleashed Head of Product & Distribution, Jarrod Adam.

The AIM module works by letting users create forecasts via a surprisingly simple interface. It then works backwards through each product’s bill of materials to reverse-engineer a plan for buying and sub-assembly requirements to match the set demand.

Crucially, the system accounts for factors like the time required for production, supplier lead time performance and any stock-out risk, so that purchasing managers can replenish via their different suppliers at the correct time – and for an optimised quantity.

“Imagine you’re a cheesemaker with a dozen different products,” says Adam. “The cheddars take months to mature – but the bries can be ready in weeks. They all use different combinations of rennets and cultures, packaging and milk. And your suppliers are a mix of local and overseas.”

“Now imagine you land a big retail deal for a handful of different SKUs. The planning involved can be a nightmare. But with AIM all you do is tell it what end products you want, when, and where – and an optimised purchasing and production plan creates itself.”

“For small teams with tight budgets, that’s a big deal – having the confidence you can satisfy customers, while only buying what you need, when you need it.”

Ease-of-use a priority

User experience has emerged as a point of difference for Unleashed, which has a strong focus on ease-of-use and intuitive interfaces in its development roadmap.

“That’s something we hear a lot about from our customers," says Adam. “They don’t want systems that take special training or extra time to learn. You want everyone on the team able to pick it up and use it straight away.”

That philosophy has led to ‘Kanban’ boards being rolled out across the software.

Kanban is just a fancy word meaning ‘signboard’, says Adam, where you basically have digital post-it notes for jobs that you can drag and drop.

“Creating a Kanban interface for production was a no-brainer, and it’s been really popular. It's just a much more visual way of organising work that helps you keep track of everything in one view, progress your jobs through different stages, match people to tasks, and let everyone see what’s going on.”

Another recent release for manufacturers – byproducts – has also been popular. The feature ensures secondary products of manufacturing processes can be tracked and accounted for. Whether that be sheet metal offcuts that are sold to scrap merchants, or spent grain from brewing used as animal feed, the new functionality gives better visibility of these common additional products and revenue streams.

Extended Producer Responsibilities – working with deposit return schemes

Rounding out the newly added manufacturing features in Unleashed is a simple but effective tool for use in container deposit schemes and similar recycling and product lifecycle tracking programmes.

While these schemes vary across jurisdictions the principles are the same, with requirements to report on and lodge payments for packaging that might enter the waste stream. Unleashed’s addition ensures any payments can be properly separated and tracked within a company’s accounts, and packaging volumes identified.

“Again, building this functionality is about making life easier for manufacturers,” says Adam. “Deposit return schemes are common around the world for everything from drink bottles to tyres. They have the potential to add complexity for manufacturers, but with a few simple features we can help them meet their obligations without headaches.

“To me that’s the key to success in serving our target market – ensuring they stay as agile and competitive as possible without getting bogged down in processes. We’ll help them with that wherever we can.”