|

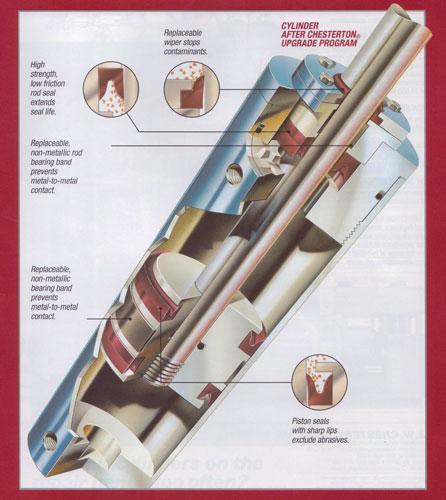

THE challenges of rebuilding hydraulic cylinders are both technical and about cost, says Doxeal’s Kevin Docherty. “It’s interesting that Doxeal earns revenue from rebuilding cylinders that ‘don’t work anymore’ – yet by upgrading the cylinders to a much higher specification and engineering out the causes of cylinder and cylinder seal failure, we’re actually reducing our prospective market, because the cylinders potentially last seven times longer,” he explains. “Over 30 years I have presented many technical solutions, often product based, to customers and often found it was a waste of time. They weren’t interested in making that extra investment and therefore many missed out on the opportunity to increase production. “Yet, on the other hand, manufacturers are constantly looking for ways to increase equipment availability and don’t want to carry spare machine parts in case of untimely equipment failure.” Hydraulic cylinder performance has improved over the years by way of higher performance materials used in the manufacture of the seals, says Docherty. “But little has been done about improving design to engineer out the major causes of failure – such as external and internal cylinder contamination, metal to metal contact within moving parts, excessive clearances, inferior design that fails to give working parts support and sufficient strength, no wiper seals to protect internal seals and wipers that cannot be replaced on the run.” This is where Doxeal’s Cylinder Upgrade Program excels. The program focuses on all the issues with the single goal of increasing equipment availability to manufacturers. The cylinder rebuild process includes: • Re-designing the cylinders, using additional support for the piston and rod. • Eliminating all metal to metal contact. • Providing replaceable wiper seals. • Eliminating excessive clearances. • Providing internal wiper seals. • Eliminating expensive gland nut replacements (usually bronze). • Providing high quality self lubricating sealing systems. Doxeal specifies world class Chesterton red polymer lifetime self-lubricating seals for its Cylinder Upgrade Program – which means operating temperature is reduced, cylinder wear is minimised and seal life greatly extended. Chesterton seals are self-adjusting in service – no gland adjustments are ever required. “With our Cylinder Upgrade Program capable of extending your hydraulic cylinder life by up to seven years, why wouldn’t you give us a call?” concludes Docherty.

|

Email: keith@doxeal.com |