How the initiative will work

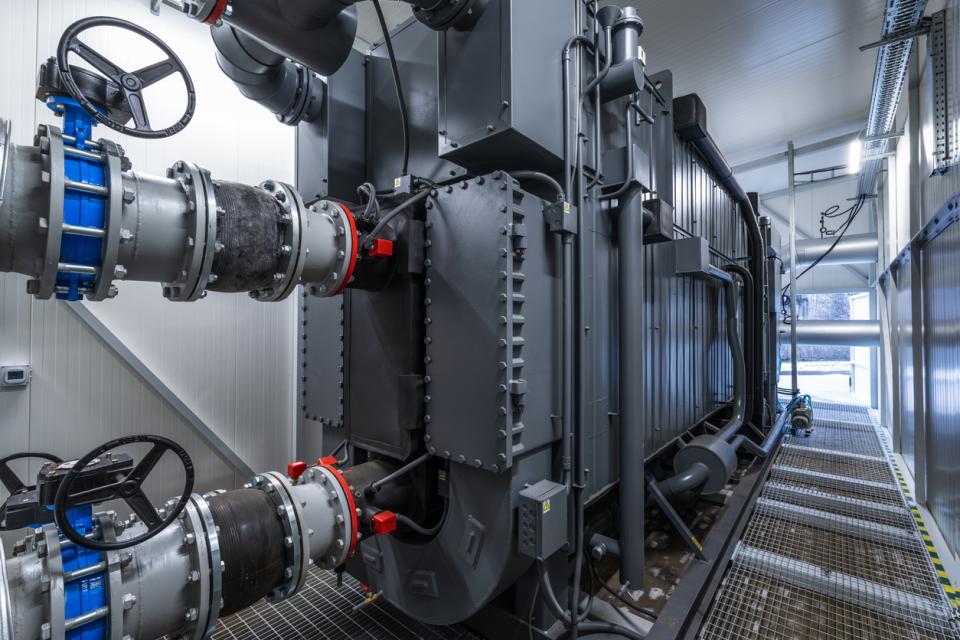

While high temperature heat pumps (HTHPs) have been available in New Zealand for some time, those that supply very high heat, including steam, are less common. HTHP technology is advancing rapidly, and commercially available units can supply process heat at 200oC or higher, including steam supply. This initiative focuses on HTHPs which supply high process heat very efficiently, with conversion efficiencies in the 200% to 400% range.

EECA will collect baseline energy data, and then data for 3 years after commissioning, to provide real-word use-cases to enable and encourage further uptake. Successful applicants will be involved in promoting their projects and sharing their experiences with others in their region and/or industry.

EECA seeks applications from New Zealand-based businesses that:

- will deliver the project in New Zealand

- have completed a feasibility study assessment of the appropriateness of the technology for their process heat requirements

- confirm they have the ability to fund 75% of the total project cost and have confirmed approval to invest in the project (or will have this within 30 Business Days of contract signing)

- will be the ongoing owner or lessee of the equipment for the duration of the project.

Applications must:

- use high-temperature process heat (≥90°C), including steam

- currently use fossil fuels or operate inefficient heat systems

- increase energy efficiency by a minimum of 150%, COP of 1.5.

Other technologies that may qualify as part of the project, if essential for the operation of the HTHP can include waste heat recovery (e.g. heat exchangers, pipework) and electricity connectivity upgrades related to the HTHP project.

Funding available

Applicants can apply for up to 50% of total eligible project costs, to a maximum of $2 million EECA co-funding per project (plus measurement and verification costs).

Co-funding has 2 components:

- Base payment – 25% of total project cost (up to $1 million).

- Contingent payment – Up to 25% of total project cost (capped at $1 million), payable under certain conditions.

Projects are expected to achieve the anticipated energy savings, so the full contingent payment is unlikely to be required.

Funding conditions:

- EECA funding cannot exceed 50% of total project cost (excluding M&V costs following implementation).

- Funding is inclusive of any feasibility study, technical design, or business case development.

- EECA payments cannot exceed 50% of actual costs expended to date.