Australian-made fastening technology radically cuts slew bearing bolting time for mission-critical cranes and loaders

Safe, fast, and precise hydraulic nut and bolt fastening technology is streamlining the process by which slew bearings in lifting and loading equipment can be serviced or replaced.

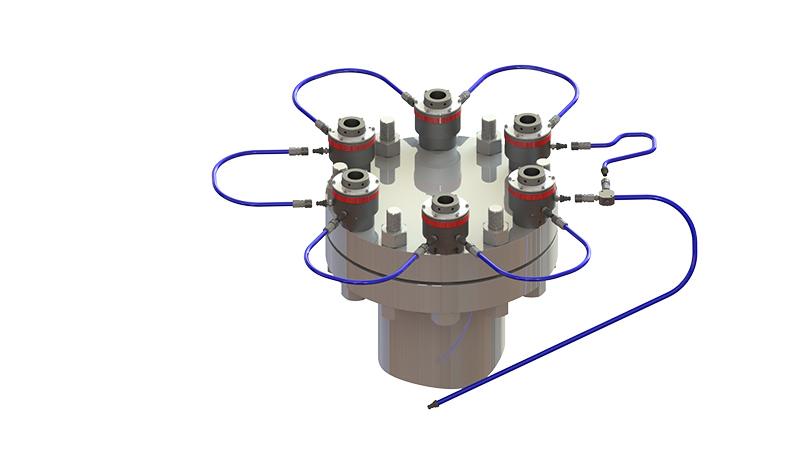

Technofast EziTite Hydraulic Nuts – designed and manufactured in Australia and used globally – can be actuated simultaneously so that groups of several or many fasteners are simultaneously tightened to exactly the same force to ensure reliable and long-lasting evenly tightened jointing vital to reliability of slewing and luffing equipment.

This is accomplished by delivering an exact hydraulic pressure through interlinked hoses to the EziTite fasteners, then tightening their individual Lock Rings to hold the generated bolt force. The force generated within the nut stretches the bolt to precise specification. Traditional methods would use a torque wrench, or manual flogging spanners one at a time. These can be hazardous to use and apply uneven jointing forces from bolt to bolt. The same groups of bolts with EziTite fasteners are easily released simultaneously for servicing by reversing the installation procedure.

Technofast Founder and CEO John Bucknell says EziTite fasteners are an advance on older and less efficient manual and hydraulic bolting technologies because they can be custom engineered to such speeds, precision, and reliability that they are used for example, on nuclear reactors and coolant pumps, or such very high-load applications where reliability and avoidance of unnecessary downtime is critical.

“We set out with a clean sheet of paper to design fasteners that are better, faster and safer – and ended up with what we believe are the best hydraulic fasteners on the market, which are being accepted worldwide by efficiency-conscious miners, bulk handlers, shippers, manufacturers, energy producers and others,” he said. Technofast has built an entirely new greenfield production site at Crestmead, Brisbane, to satisfy global demand for the product.

An example of an EziTite application is where groups of the nuts were deployed at an Australian iron ore port that has enabled operators of a 5,000 TPA ship loader to tension bolts during slew bearing replacement more than five times faster than by using conventional torquing or hazardous manual methods.

A total of 72 specially designed Technofast EziTite Hydraulic Nuts were used at the Karara Geraldton Port to tension grade 12.9 studs that secure the slew bearing of the loader, which is a vital materials handling installation with long travel, luffing and slewing capabilities.

Applications include rotating, vibrating, turbine, heat exchanger and mineral processing equipment including stamping, crushing, dragline boom supports, high pressure grinder rollers, hoists, slewing tower cranes, heavy load support and mobility including civil engineering equipment, conveyor drives, motors and shells.

“EziTite Hydraulic Nuts such as those deployed at Karara are ideal for tensioning all of the studs on a flange, joint, or cover simultaneously, loading entire groups of fasteners at once. This simultaneous tensioning gives an extremely accurate and even load onto the flange/joint, enhancing its long-term security, safety and reliability,” said Mr Bucknell.

At Karara, the EziTite nuts were simply placed in position by hand then groups of four were linked together and pressurised simultaneously, reducing bolt load scatter and offering dramatic time savings.

“Using torque wrenches, for example, it would have taken about 30 minutes to tension four bolts, whereas the EziTite fasteners completed the task in less than five minutes,” said Mr Bucknell.

“Also, there are no pinch points associated with Technofast tooling and it does not need to be handled whilst being pressurised, eliminating inherent health and safety hazards.”

The EziTite Hydraulic Nuts also overcame bolt load scatter problems commonly encountered with standard slew bearing replacement procedures using torque wrenches. Bolt load scatter, due to a single bolt being fastened at a time, could have caused undue wear on the slew bearing, leading potentially to downtime on this particular application and on scores of others where slew bearings are mission-critical.

“The mining and materials handling industries are highly focused on eliminating bottlenecks in their output systems, especially those created by unnecessary time losses and ongoing maintenance arising from joint security may be less than ideal.”

Benefits of the EziTite Hydraulic Nut

- Reduce maintenance down time.

- Improve safety on the job.

- Give reliable and precise tensioning.

- User-friendly.

- Fast to fit and remove.

- Requires little physical effort.

- Is ideal for difficult or confined spaces.

The EziTite Hydraulic Nut is Ideal where:

- Accurate and reliable loading is required on bolting.

- Vibrational or torsional stresses are a problem.

- Regular maintenance requires repeated adjustment or removal of nuts.

- There are confined or difficult nut locations.

Technofast customers globally include Bechtel, BHP, BMA, Monadelphous, OneSteel and Rio Tinto.