In the race to optimise business, consolidating your warehouse footprint may not be the first strategy that comes to mind. Yet according to Jason Wu, Business Development Manager for AutoStore Australia and New Zealand, it may be a formidable solution to a number of business challenges.

“Taking into account the rising cost and scarcity of warehouse space, increasing customer demands and the rise of eCommerce, consolidating your warehouse space can enable significant gains in efficiency, productivity and cost savings,” he says.

The benefits of consolidating your warehouse footprint

“In today's competitive marketplace, where every square metre and every minute count, it's crucial that your warehouse is optimised and operating at its full potential. From improving inventory management to enhancing customer satisfaction, there are significant benefits that come with consolidating your warehouse,” explains Wu.

These benefits include:

- Increased efficiency: Consolidation allows you to optimise your space and streamline operations. “It’s about reducing the distance between picking, packing, and shipping areas. With everything in one central and accessible location, warehouse personnel can access inventory more easily, and fulfil orders faster. This efficiency translates into shorter fulfilment times and ultimately, happier customers,” explains Wu.

- Improved inventory management: Once all your stock is in a centralised location, it becomes easier to track and manage stock levels accurately. “This improved visibility prevents overstocking and wastage, or stock shortages. This is especially beneficial for the retail sector, where seasonal fluctuations and promotions are a factor,” notes Wu.

- Improved performance: With improved efficiency and accurate inventory management comes faster order processing times and reduced fulfilment errors. “At a time when customer satisfaction depends on fast, efficient service, this is key to business success,” explains Wu.

- Cost savings: Managing multiple warehouses – or even one large space – usually entails additional costs for rent, utilities, maintenance and staffing. “Consolidating your warehouse into a single, efficient facility allows you to reduce these overhead costs significantly,” says Wu.

- Streamlined logistics: Having a dispersed warehouse operation often leads to complex logistics processes. Consolidation simplifies this, resulting in smoother operations and execution.

Why automated cube storage is your go-to consolidation solution

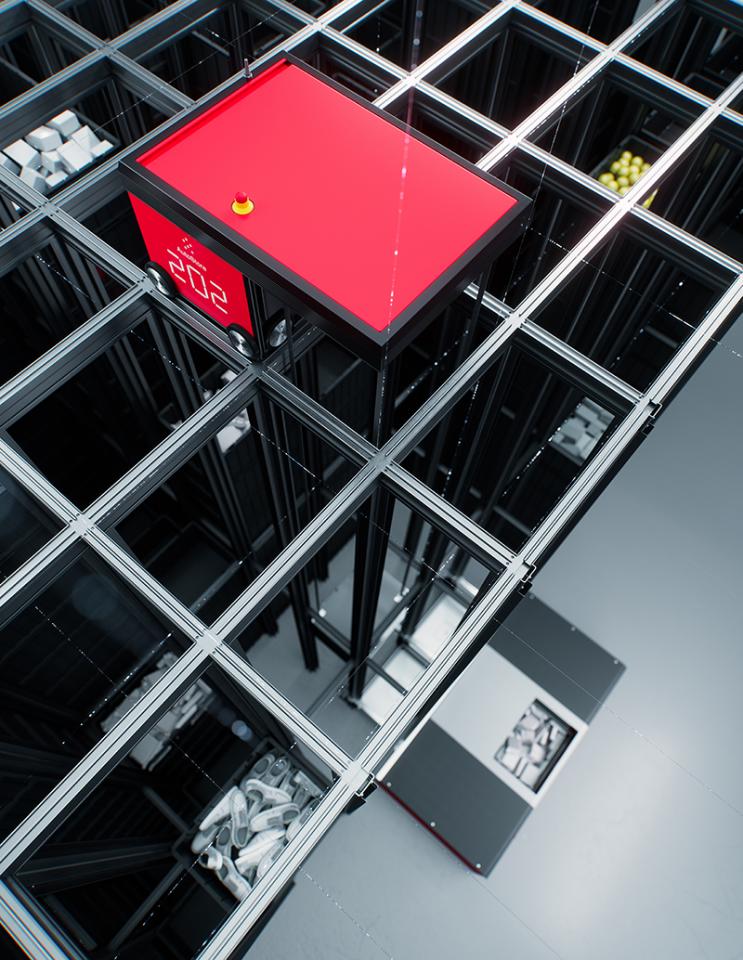

Wu reiterates that cube storage, where items are stored in individual Bins, within a Grid with a cubic design, is an ideal consolidation solution. “You significantly reduce your storage footprint while increasing your storage density. In turn, this reduces your real estate costs, presenting you with more space in which to stock product,” he explains.

This enables you to:

- Significantly reduce your storage footprint while increasing storage density, so you can reduce your real estate costs and stock more products.

- Speed up your service with higher throughput.

- Have greater visibility, for accurate inventory management.

- Achieve lower costs per fulfilled order, with savings on labour and energy costs.

- Gain improved control over the movement of goods with 100% access to inventory.

Adding automation to this system allows for further optimisation.

“In the AutoStore Grid – and in particular, the Automated Storage and Retrieval System (ASRS) –Robots access the Bins to retrieve or store items. The Robots transport the Bins to goods-to-person stations, where the items are packed for fulfilment,” he says.

This AutoStore ASRS system offers faster and more efficient storage, retrieval and dispatch of goods than any other warehouse setup. This system processes orders at record speed, offering the fastest Goods to Person system per square metre, enabling order fulfilment times of less than a minute from order to shipping. “At our fastest site, our automated storage and retrieval system (ASRS) presents 20, 000-plus bins per hour,” comments Wu.

The AutoStore system is modular and flexible, able to scale up or down to meet requirements. “In addition, it’s energy efficient as our Robots utilise about 100 Watts during operation. 10 Robots use less energy than a standard vacuum cleaner,” says Wu.

What Siemens gained through a warehouse consolidation strategy

In 2019, Siemens partnered with AutoStore to install a warehouse system into its 34,002 m2 production and distribution warehouse in Chemnitz, Germany. The goal was to consolidate its warehouse operations.

The new AutoStore warehouse system (empowered by Dematic) takes up two levels, with a condensed 760 m2 Grid, comprising 16 layers and 45 080 Bins. The flow of materials has been automated, with a conveyor line carrying filled Bins into the Grid (where Robots handle the picking and fulfilment). Incoming goods are distributed to workstations on the upper level, while empty Bins travel to the workstations on the lower level.

“Following implementation of this system, Siemens achieved a 40% saving on staffing costs and a 60% saving of storage space. They recorded increased picking rate of 78% with fewer errors, even during round-the-clock operation,” concludes Wu. “This is a great case study in the positive effects of consolidation of warehouse footprint, with the goal of optimising space and storage density, while bolstering