Schaeffler is introducing a compact wind turbine tapered roller bearing unit with a direct flange mounting facility to make installation logistics and mounting significantly easier.

Schaeffler Australia Power Transmission and Wind Energy Sector Manager, Ben Kang, said the new designs complement the latest Schaeffler spherical roller bearings that have been optimised to the last µ (coefficient of friction), including new asymmetric spherical roller bearings that allow wind turbines to generate energy even more reliably.

“These new technologies are particularly timely given the expansion of wind power as a proportion of renewables generated in Australia and New Zealand. Ease of installation and reliability in service are key requirements of both countries’ programmes, with more than 4,300 megawatts of wind energy already accounting for a third of renewable energy produced in Australia and with New Zealand aiming to rapidly expand installed capacity of more than 609 megawatts operating or under construction,” he said.

Robust bearing technology is particularly vital to the reliability of wind power, says Kang. “Because all the forces from the wind act directly on the rotor bearing support in a wind turbine, rolling bearings are subjected to highly dynamic loads and operating conditions. A range of powertrain designs have established themselves on the market, each of which requires a different bearing support. Schaeffler has therefore optimised proven bearings and, at the same time, developed new bearing designs for various bearing support concepts.”

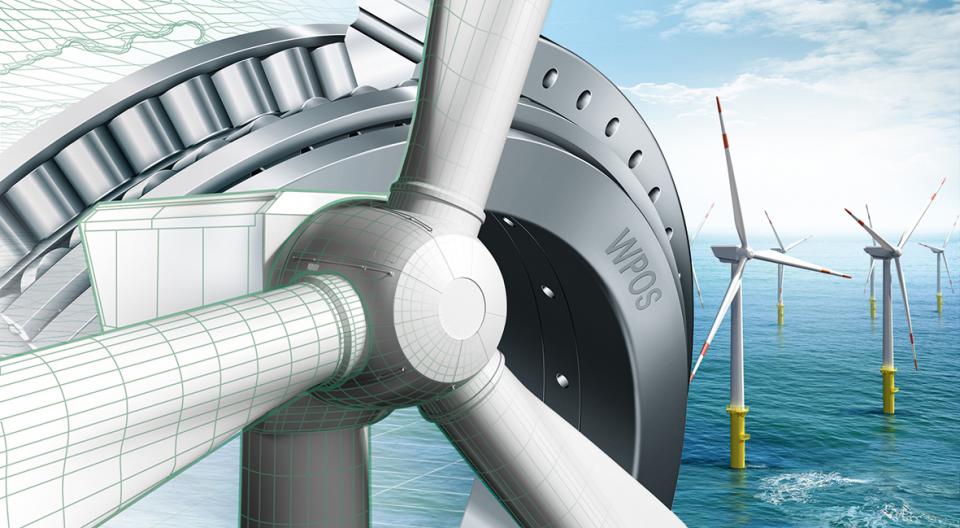

FAG flanged bearing unit: Compact and easy to mount

Kang said the new flange-mounted tapered roller bearing unit allows all forces and moments in a bearing to be safely supported, owing to the large pressure angle and tight axial guidance of the rotor. The double row tapered roller bearing unit in O arrangement, with grease lubrication and seals, is supplied pre-assembled. The inner rings are flange-mounted to the rotor, while the outer ring is flange-mounted to the nacelle. The bearing clearance is pre-set, which significantly reduces logistics and mounting costs.

As an option, the flange-mounted tapered roller bearing unit can be fitted ex works with FAG GreaseCheck. GreaseCheck’s grease sensor is parameterised to the specific type of grease and provides optical measurement of the water content, turbidity and mechanical wear, as well as the grease temperature directly, in the bearing support.

Ongoing development

Schaeffler says it is using over 30 years’ experience producing bearings for wind turbines to further optimise the cost-effectiveness and reliability of its wind power products, technologies and maintenance services for the Australasian market.

To meet the increasing demands for reliability in wind power systems and components, Schaeffler created the Wind Power Standard (WPOS).

In order to achieve the high standards, Schaeffler says it relies on coordinated and transparent processes, defined change management, strict quality monitoring, and extensive documentation across the entire process chain in close cooperation with customers and suppliers.

Schaeffler’s own large-size bearing test rig ASTRAIOS contributed to the development of the flange-mounted tapered roller bearing unit. Ever since ASTRAIOS was put into operation in 2011, it has been supplying important information on features which could previously not be tested, such as sealing and lubrication concepts and operating clearance (influence of the temperature and connecting screws) and roller speed.

Bearings up to 3.5 metres in outside diameter can be tested on one of the most state-of-the-art and biggest large-size bearing test rigs in the world. ASTRAIOS simulates the real loads and torques that occur in a wind turbine. Schaeffler uses these realistic simulations to contribute decisively to a faster and more reliable design of wind turbines and increases their cost-effectiveness and safety.

To increase the reliability, availability and therefore the economy of wind turbines, Schaeffler has optimised its spherical roller bearings for main rotor bearing supports. This bearing design is used exclusively on the so-called shaft bearing support – the most frequently occurring bearing support concept. To optimise the bearing, both its micro and macro geometry were addressed. The result is conclusive: It was possible to reduce friction and pressures in the bearing, to improve the distribution of forces, and to increase the axial rigidity. These optimised spherical roller bearings therefore have greater resistance to the wear which specifically occurs as a result of axial displacement. These bearings successfully completed a comprehensive range of tests as part of their validation for the Schaeffler “X-life” quality seal. The validation steps required for this have been certified by Germanischer Lloyd (GL certificate GL-CER-002-2015).

Details, Ben Kang, E-mail: Ben.Kang@schaeffler.com