Gates says it has set a new benchmark for innovation and quality in the ultra-competitive V-Belt market with the launch of the first 100 percent service free belt, the Quad-Power 4. These latest generation EPDM belts deliver an extended service life and have been designed to eliminate costly downtime for re-tensioning, repair and replacement.

“Our new Quad-Power 4 is the first truly service free raw edge V-belt range,” said Phil Aitken, Product Application Engineer, Gates Australia.

Gates has invested heavily in research and development to design a belt incorporating minimal-stretch cord technology, which provides it with the confidence to assure users that the new Quad-Power 4 is the industry‘s first raw edge zero-maintenance V-belt.

Unlike conventional belts, the Quad-Power 4 raw edge V-belt does not suffer from severe tension decay in the first hours after installation. This negates the need for a run-in period and ensures that the belt will never require retensioning throughout its service life.

“Just imagine how convenient this is for difficult-to-reach belt drives,” says Aitkin. “No retensioning means no machine or production downtime.”

Gates reckons there is little doubt that the all new Quad-Power 4 service-free V-belts will quickly become popular with plant engineers and maintenance managers. This new generation of V-belts has the potential to not only reduce down-time costs, but they can also increase both efficiency and profitability.

“In addition to negating any service requirements, our Quad-Power 4 also deliver greater efficiency, higher performance and are designed to work in a wider temperature range than traditional V-belt technology allows,” said Aitkin.

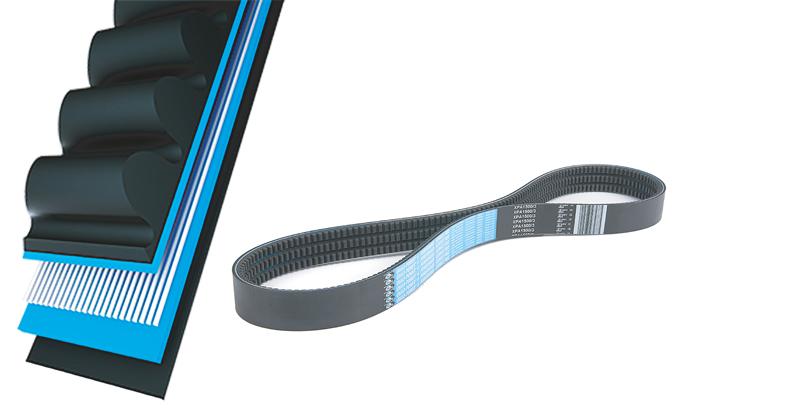

The new raw edge, moulded notch construction not only saves on downtime and maintenance costs, but by using state-of the-art profiling technology, guarantees consistent pulley/belt contact resulting in energy efficiencies as high as 98 percent, or 3 percent higher than wrapped V-belts.

Aitkin says that installing Quad-Power 4 belts means delivering lower energy consumption and an improved drive performance at the same time.

The new Quad-Power 4 V-belt remains crack and damage-free in extremely high and low temperature conditions. “The Quad-Power 4 belt maintains its exceptional performance in extreme cold conditions as low as -50 °C,” says Aitkin. “The newly formulated EPDM rubber material resists hardening to avoid cracking in temperatures up to +130°C making the Quad-Power 4 belt the ideal solution for hot air HVAC applications or other high temperature environments.”

As an engineering leader with a strong foundation in research and development, Gates is committed to advancing the science of motion performance by developing safe, forward-thinking products, services, systems, and solutions stating the all-new Quad-Power 4 V-belts delivers on this commitment and there is no doubt that it sets a new industry benchmark for quality, innovation and performance.

Gates Quad-Power 4 belts will supersede the existing Quad-Power III belts, and will be available as Quad-Power III belt stock is depleted.