Cut To Size Plastics has been recognised in the innovative technology category of the 2016 Bulk Handling Awards for its split plummer blocks, which can be particularly valuable for maintenance tasks where production and process staff want to minimise disruptions to production caused by bearing replacement and traditional bearing failure.

The awards, to be held at Doltone House in Sydney on November 24th, recognise the most innovative, efficient and safe technologies in the bulk handling industry.

“It’s fantastic to be recognised amongst other industry leaders for innovative technologies like the split plummer blocks that save downtime for busy bulk handling companies,” said Mr Laurie Green, Managing Director, Cut To Size Plastics.

“Split plummer blocks are an ideal maintenance solution, when production shutdowns just aren’t an option,” he said.

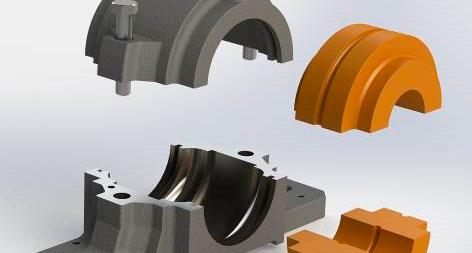

Split Plummer Blocks

Light, easily handled and self-lubricating spilt blocks can be precision machined from polyurethane and other engineering grade plastics for diverse materials handling applications, often involving machinery with multiple bearings and shafts inline where it would be costly to close down the entire line for removal and installation of heavier and more complex bearings.

“Often engineering grade polyurethane bearings, with a shore hardness of 75D, provide an excellent interim solution that saves time and money, while in other situations they provide a highly cost-effective long life solution,” says Pat Flood, NSW Manager of Cut To Size Plastics, which has been supplying Engineering Plastics to Australian and international customers for over 35 years.

Polyurethane split plummer blocks – which are designed for quick removal and installation - provide advantages that traditional bearings do not, including:

- Light weight for speed and OHS benefits

- Self-lubricating for production security and time savings

- Wear improvements

- Tear and weather resistance

- Heat and cold resistance

- Lower operating costs

- Long life

- Noise abatement

- Capable of working in extreme wash-down applications

- More sanitary

“Polyurethane has been widely proven in robust materials applications - including in the timber industry, for example – offering industrial applications the elasticity of rubber combined with the toughness and durability of metal, to reduce plant maintenance and OEM product cost,” says Mr Flood.

“Urethanes have replaced metals in many applications, including sleeve bearings, wear plates, sprockets, rollers and diverse other components. Parts made of polyurethane will often outwear other materials by margins of 5-50 to one when severe abrasion is a maintenance issue.”

“Where the split blocks are used in particularly corrosive or aggressive environments – ranging from food and beverage through to primary production and handing of chemicals involved in resources processing – the blocks can be engineered from other high performance plastics particularly suited to the particular task,” says Mr Flood.

In addition to split plummer blocks, the company engineers a wide diversity of machinery components and Hercules brand load and slip bearings used extensively by industries ranging from architecture and construction to production and process engineering, manufacturing and materials engineering, mining and energy, timber, paper and primary product processing, food and beverage, agricultural product processing, water and waste water.

We will cut it, rout it, bend it or machine it, all to your specifications. Our comprehensive CNC machining facility at Yennora, coupled with GibbsCAM™ and Solidworks™ software make it easy to deal with us. Your drawings go into our computer – then to the CNC machines.

Cut To Size Plastics Pty Ltd – headed by Managing Director Mr Laurie Green - has been supplying Engineering Plastics to Australian and International customers for over 35 years. The company is committed to meeting Australian and International Quality Standards and to working within the guidelines issued by State workcover authorities.

The company holds extensive stocks of Nylon, Oilamid, Acetal, Teflon and UHMWPE combined with HDPE, PVC and Polypropylene to complement service to Australian Industry. The company also has access to the most advanced engineering plastics worldwide.

For further information in NSW or nationally, contact Pat Flood, Cut To Size Plastics, +61 2 9681 0400

pat@cuttosize.com.au

For further information in Queensland or Northern Territory, contact Frank Domajnko, Cut To Size Qld/NT Manager

+61 7 3276 6700

frank@cuttosize.com.au