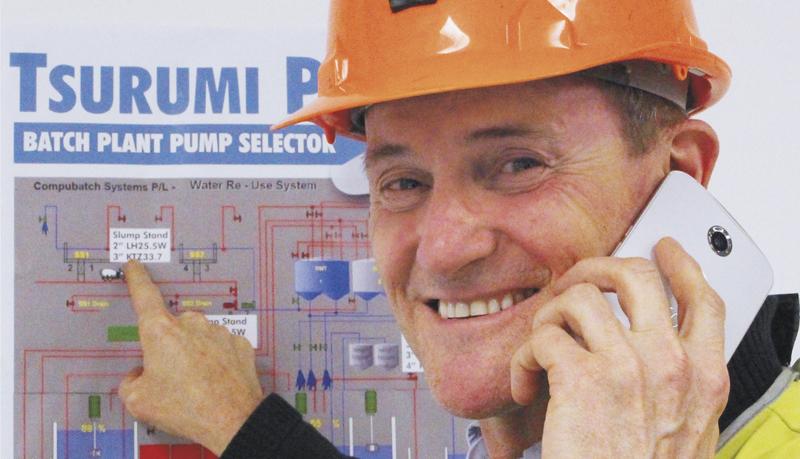

Concrete batch plants across the country are reducing downtime and slashing maintenance costs thanks to the Australian Pump Batch Plant Pump Selector, reports the company. The guide shows plant managers what pumps should be applied at various points of the batch plant, making pump selection simple.

“Our research showed us that misapplied pumps are a major problem in batch plants. When a pump goes down the urgency of the situation often means that the replacement is chosen on availability rather than suitability,” said Aussie Pumps’ Neil Bennett. “We want to help plant managers to understand that the abrasive nature of batch water means that correct pump application is key to improved plant efficiency. Our pump selector guide that takes the mystery out of pump selection,” he said.

Guide to cost cutting

The pump guide identifies the correct pumps to be used at the various stages in the plant. From first flush and wedge pits through to stirrer pits, the recycled water contains various concentrations of cementitious material contaminated with aggregate, slag and iron fillings.

The new guide features Tsurumi KTZ cast iron pumps for handling slag and dirty water through to high head LH pumps for delivering water under pressure for tall slump stands and wash-down of trucks.

Tsurumi KTZ pumps … cast iron performers

The Tsurumi range of KTZ dewatering and slurry pumps are designed specifically for this type of application. They incorporate wear resistant hi-chrome iron impellers that enable solids in suspension to pass smoothly through the pumps.

Tsurumi Pump is the world’s leading manufacturer of submersible pumps with an annual manufacturing capability of over 1.4 million pumps. With over ninety years’ experience they have developed a comprehensive range of robust, super-efficient pumps for use in concrete batch plants.

“The abrasive nature of batch water can be a real killer for normal submersible pumps. The Tsurumi KTZ range use hi-chrome iron internals that resist wear making them ideal in this application,” Bennett said. “They are already used extensively in batch plants around the world. Their popularity is also due to Tsurumi’s no compromise ethic that incorporates features that extend pump life as standard in all their pumps,” he said.

The KTZ series offer capacities of up to 2,400 litres per minute flow, and heads as high as 48 metres. This means loading batch water from the holding tanks is fast, cutting the waiting times for trucks at the hoppers and slump stands. 2”, 3” and 4” pump configurations are available to suit the existing pipework.

LH-W Series … high head achievers

Recycled water used at slump stands often fulfils two uses. Firstly, to control the slump mix and secondly, to wash down trucks before they leave the stand.

When the slump stand is positioned away from the collection tanks or if the stand is particularly tall, the pumps will need to deliver high head performance.

Tsurumi 2” LH25.5W series pumps recommended for use in these applications because they deliver heads to 60m and flows to 465 lpm. They incorporate twin hi-chrome iron impellers and use a heavy duty 5.5kW motor.

Submersible advantages

Although surface mount pumps may be easier to monitor and service, submersible pumps have a number of advantages in this application.

- Submersibles can be used with flexible discharge pipes. This makes the system easy to install and remove when the settling pits need to be excavated.

- Submersible pumps self-flush when switched off thus preventing clogging due to settling solids in the pump.

- Submersible pumps self-prime, making them easy and fuss free to set up again after service or for fast emergency deployment.

“Tsurumi have made their name supplying pumps for the concrete industry around the world,” said Bennett. “We want Australian plants to get the cost cutting benefits these pumps bring,” he said.