The manufacturing industry is on the verge of entering into the next industrial revolution called Industry 4.0 and it is going to change control systems architecture, system connectivity and sensors as we know it today. A lot of the data from the devices will be analysed on the internet and hence Internet of Things (IoT) will be a big part of Industry 4.0. The field which relates to industrial data to the internet is further referred to as Industrial Internet of Things (IIoT).

The next industrial revolution – Industry 4.0

The term “Industry 4.0” refers to the fourth industrial revolution. It originates from a project in the hightech strategy of the German government, which promotes the computerisation of manufacturing. The first industrial revolution was the mechanisation of production using water and steam power. The second industrial revolution then introduced mass production with the help of electric power, followed by the third digital revolution and the use of electronics and IT to further automate production.

The convergence of cheap processing, unending storage, massive bandwidth, near-ubiquitous connectivity, and cloud-based applications is driving new capabilities for gathering information and changing the way we interact with machines and services. The data generated by sensors in this network of connected devices is being collected and analyzed, spawning the growth of big data analytics and applications. And the resulting analytics are being used to improve business efficiency, better serve customers and disrupt old business models.

What is IoT (or IioT)?

Simply put this is the concept of basically connecting any device with an on and off switch to the Internet (and/or to each other). This includes everything from cell phones, coffee makers, washing machines, headphones, lamps, wearable devices and almost anything else you can think of. This also applies to components of machines, for example a jet engine of an airplane or the drill of an oil rig. If a device has an on and off switch then chances are it can be a part of the IoT. Microsoft predicts that in 2020, the worldwide market for Internet of Things solutions will amount to US$7.2 trillion with 25 billion “things” connected. Some of the benefits of IoT are mentioned as below. • Tracking behaviour for real-time marketing, • Enhanced situational awareness, • Sensor-driven decision analytics, • Process optimisation, • Optimised resource consumption and • Instantaneous control and response in complex autonomous systems.

Is there anything needed to get the data from factories into cyber physical space?

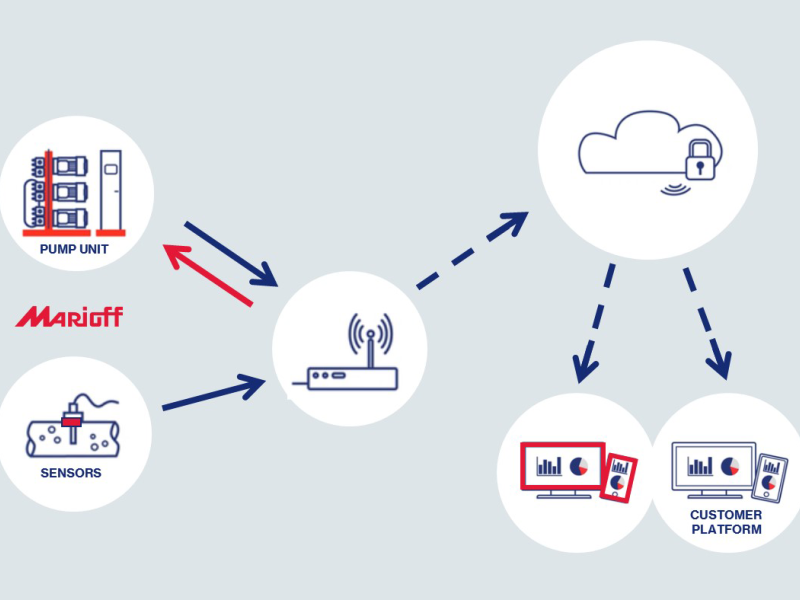

To get the data from the factory floor to cyber physical space (i.e. to the internet/cloud), both hardware and software is required. With the introduction of IO-Link technology and smart IO-Link sensors the hardware platform is defined.

But the key is to get the software solutions which complement the hardware sensor technology. It is believed that currently only one percent of the information from machines are analyzed. Imagine the possibilities if 100 percent of the data from the machines can be analyzed and stored to allow comprehensive and meaningful analytics ensuring best optimum operations of the machines and enhanced quality of the products.

Ability to talk multiple interfaces being vendor independent

Another important factor of the software to be used in the IoT sphere is the ability: • to communicate with multiple vendors and file formats cost effectively; • to be vendor independent; • to be a universal communication system from the physical systems on the factory floors to the cyber physical space; • to extract 100% of the data from the system and provide to the internet; • to read and write to and from the physical machine and/or system.

Real-time and historical views

It is important for the user of the system to be able to view real-time data and be able to make changes to the process and analyze historical data (both locally and/ or remotely). Armed with all this data in an easy-to-find central location will enable the user to analyze and improve system efficiencies more effectively.

Alarm Management

In today’s modern world virtually everything is controlled and communicated to a smart device such as a smartphone or tablet. Therefore the ability for the software to provide users with real-time alarm event information via SMS or emails and/or view a history log of all previous alarms which have occurred directly to their smart device is a must and no longer an optional feature.

Data directly into ERP system

Getting the data into the ERP system and to the cloud cost effectively has always been a challenge. But with the introduction of unique software offerings, parallel communication between factory floor sensors, PLC’s and ERP is now possible. This communication is classed as Y-Path by ifm efector which is illustrated by the picture below and allows for smart IO-Link sensors to communicate not only with the PLC, but directly with ERP systems such as SAP.

The perfect solution

An out-of-the-box product that addresses the challenges mentioned in this paper and aligns the user towards IIoT, is ifm efector’s SMARTOBSERVER software which offers Energy Efficiency and Condition Monitoring via easily customised viewing cockpits.

Results that can be obtained from the software are: • Live display of the current situation and time series • Alarm for preventive maintenance tasks • Trend display and energy consumption measurements • Alarm escalation strategy • Time series as a table and graphics with signal limits • Live status with access to system messages • Implemented in a web server or alternative installation on the machine • Production-specific evaluation of process values • Benefits that can be obtained from the software are: • Optimisation and reduction of the energy consumption • Cost reduction in the entire manufacturing process • Continuous condition monitoring of machines and installations • Organisation for preventive service and maintenance • Process reliability of the installations • Organisation of maintenance • Quality assurance of the produced products.

Conclusion

In order to adapt to the future smart factory or Industry 4.0 concept, it is inevitable to ensure that your factory is IIoT ready. Ifm efector is a company that is able to assist in getting your factory “Industry 4.0 enabled” with their diverse range of products. From its smart IO-Link enabled sensors, smart connectivity systems, LineRecorder MES software, SMARTOBSERVER software and SAP connectivity solutions – they are in the perfect position to assist and partner with you through what is going to be a very interesting time ahead.

For further information

Contact IFM NZ Support

0800 803444

sales.nz@ifm.com