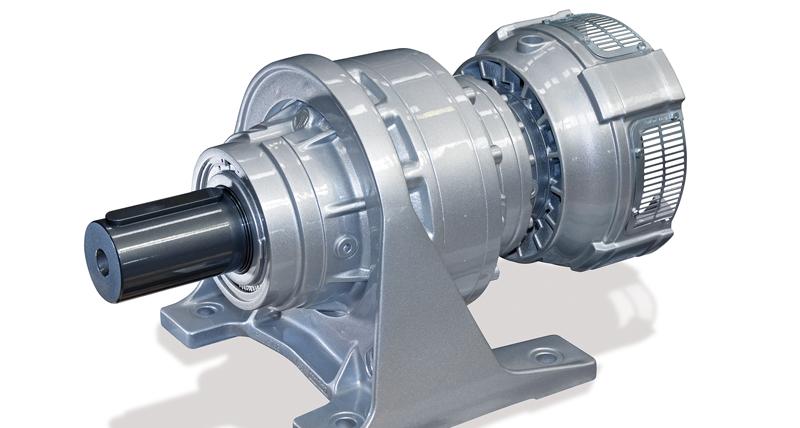

To enhance the performance of its Trasmital planetary gearboxes, Bonfiglioli is introducing an integrated fan option on its new 300M series. The fan is connected directly to the IEC motor, which leads to an improved thermal rating and increased thermal power of up to 217 percent, depending on the model.

Planetary gearboxes are staple workhorses for bulk materials handling, mining process equipment, food and beverage, materials handling, water treatment, waste handling and heavy industries. They typically use a low speed and high torque for reliable performance in a compact space.

The high levels of torque together with the compact nature of planetary gear units can lead to thermal restrictions.

“The new thermal drives with integrated fans run much cooler than their predecessors, which means they can safely utilise more torque,” explains Malcolm Lewis, Managing Director, Bonfiglioli Australia. “Because more torque is available, some applications will be able to use a smaller gearbox to do the same job, saving space, power and cost. The new range is ideally suited to hot climates. Having an integrated fan also has maintenance benefits, as there is no external cooling unit. Additionally, there are fewer overall components, which reduces the chance of a small part failure causing the entire gearbox to need maintenance.”

The integrated fan is connected to the IEC motor flange in a compact and efficient way, says the manufacturer. A keyway hollow shaft connection with the motor means that no joint is required. Integrated fins optimise the air flow and cooling surfaces throughout the entire air conveyor housing.

“No additional water or oil cooling system is needed with the integrated fan, making it an even more environmentally friendly and sustainable option than option than other cooling mechanisms,” said Lewis.

The integrated fan is designed to fit any size Bonfiglioli or commercial motor and the 300M series has 100 percent interchangeability with Bonfiglioli’s current 300 series models, so no machine modification is required when upgrading to the new units.

Major applications for the 300M series include:

- Mining – car dumpers and stacker reclaimers.

- Materials Handling – screw conveyors and apron feeders.

- Cranes and Winches – jib cranes and ship loaders.

- Food and Beverage – spiral freezers and flaking machines.

- Water and wastewater – mixer agitators and band screeners.