While radial shaft seals are a relatively low-cost item in a rotating machine, they often have a much larger influence on the maintenance costs and overall rotating equipment performance.

While radial shaft seals are a relatively low-cost item in a rotating machine, they often have a much larger influence on the maintenance costs and overall rotating equipment performance.

Seal leakage can have costly results from product or process contamination or worker health and safety, and maintenance costs from reduced service life are often significantly higher than the cost of the seals.

The impact of using an unsuitable seal in an application can be expensive repair costs, and just because a seal fits, or is the same as the seal that was removed does not necessarily mean it is the best solution for the operating conditions.

Choosing the right seal for an application can depend on several different factors, and a standard seal may not be the most cost-effective solution.

Materials

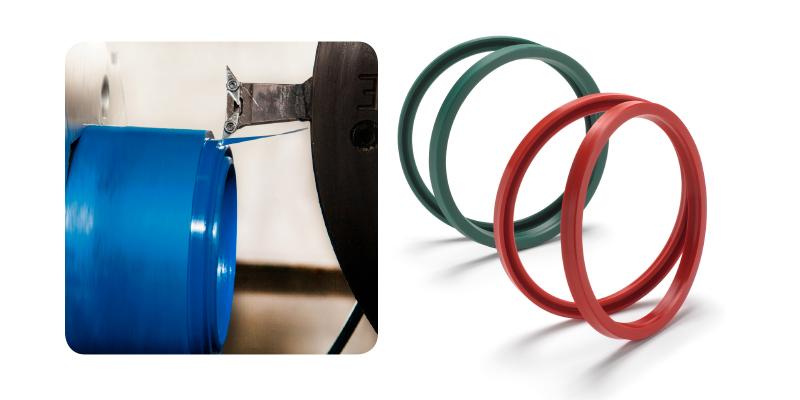

Seal material selection can have a significant impact on the overall performance and reliability, and each material has advantages and disadvantages. SKF sealing lips are generally made of elastomer materials such as nitrile rubber, thermoplastic elastomers such as polyurethanes, or thermoplastics like PTFE.

Selecting an appropriate seal material depends on the operating conditions of the application. The influence of a single operating condition typically dominates the seal selection process, such as chemical resistance or temperature, and can limit the range of suitable materials.

SKF sealing solutions for food and beverage manufacturers for example draw upon a variety of specialty material types to meet the sectors’ specific requirements for hygiene, structural integrity and resistance to caustic cleaning agents. These include high performance polyurethanes that offer excellent abrasion and wear resistance, low compression set and high tear strength.

Temperature

At low temperatures, a sealing lip can lose its elasticity and becomes hard and brittle, sealing efficiency will decrease and the seal becomes more susceptible to mechanical damage. At high temperatures, the material can age and harden while at the same time the lubricant film often breaks down, resulting in insufficient lubrication and seal lip wear, which is one of the most common causes of premature seal failure.

Common nitrile rubber seals have recommended operating temperatures of between -40 to 100°C, however the seal lip temperature is influenced by the ambient temperature and the adjacent component temperature. Friction heat generation between the seal lip and the contact surface plays an important part in seal selection, and is strongly influenced by seal speed, lubrication and shaft diameter.

Customised seals

When extreme operating conditions or unique application demands prove to be more than standard catalogue sealing option can handle, SKF can help with specialised solutions. The SKF machined and moulded seals offer provides benefits from high performance engineered plastic materials to deliver reliable, long-lasting seal performance in conditions that would cause conventional elastomer seals to fail.

For further information, please contact your local SKF Authorised Distributor or email customerservice.nz@skf.com.