It’s hard to believe that TwinCAT software is almost 30 years old. This world-renowned software suite was initially developed by Beckhoff Automation in response to changing market demands and has come a far way since its inception.

Speaking to its long-standing history, Supriya Suhale, Category Manager - Connectivity for Beckhoff Automation explains that the company was founded in 1980 when nuclear physicist, Hans Beckhoff, began building control cabinets for customers of his parents’ electrical installation business. From its humble beginnings as a one-man business, operated out of a small storage space, Beckhoff Automation would go on to become a leader in the development of automation systems that enhance manufacturing processes.

“In 1986, we produced our first PC-based controller system and in 1996, the first commercial version of TwinCAT was launched,” says Supriya. “Looking back, it’s unbelievable to think about how instrumental this innovation was in shaping the industry that we know today.”

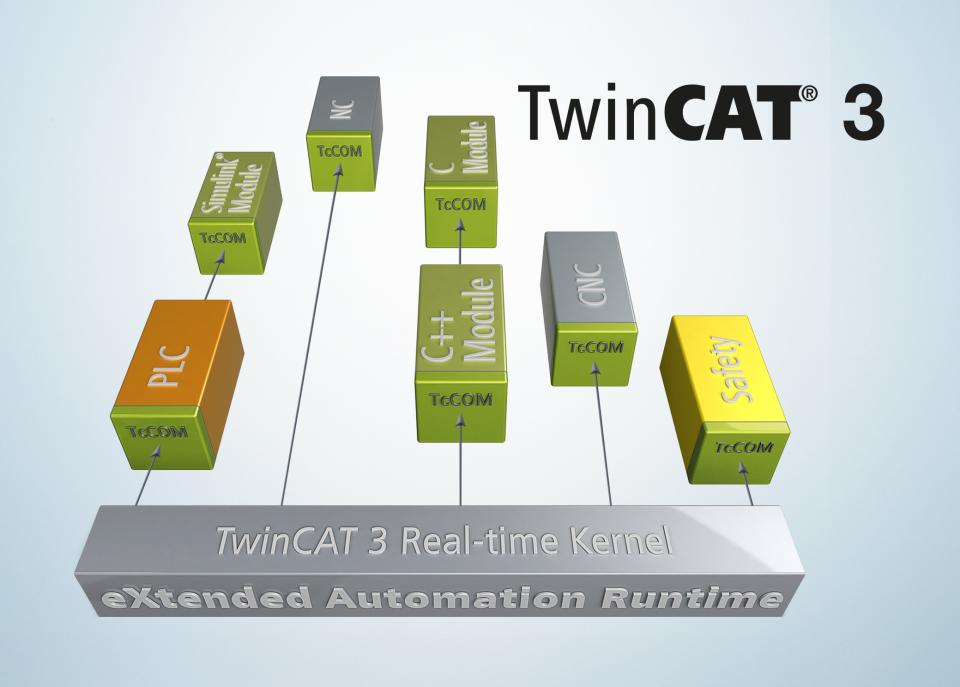

While TwinCAT needs no introduction, Supriya explains that “it is an integrated development environment used to transform almost any PC-based system into a real-time control solution with multiple PLC, NC, CNC and robotic runtime systems.”

And while it may seem obvious now to hand over industrial control to a PC, this is only thanks to innovations like TwinCAT that helped make it possible. “Our software was one of the first to make use of a PC with Windows as an operating system,” notes Supriya.

TwinCAT 3 at APPEX 2024

Now in its third generation, APPEX 2024 (previously AUSPACK) is the ideal exhibition for the launch of TwinCAT 3 (the latest generation of TwinCAT technology). Beckhoff Automation will be exhibiting at this industry-leading exhibition taking place from 12 to 15 March 2024 in Melbourne.

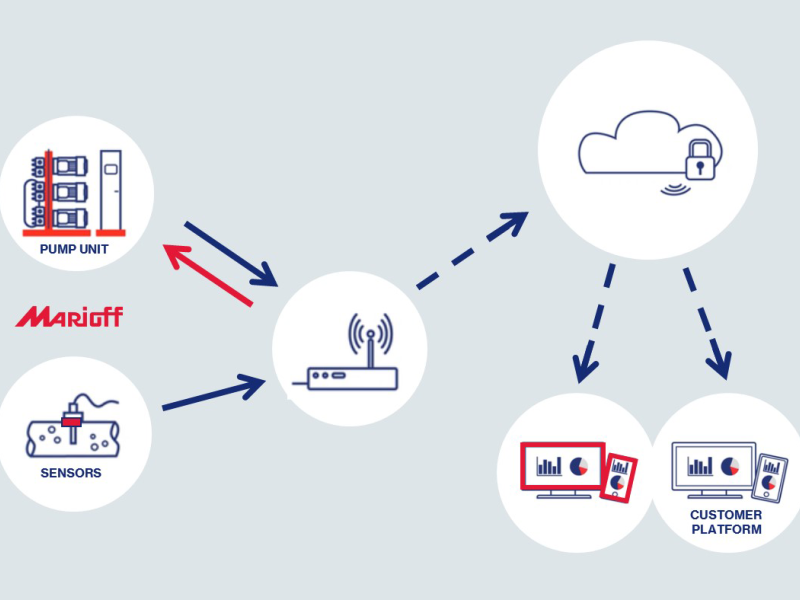

“TwinCAT 3 enables seamless integration of machine learning, vision, edge computing and cloud connectivity – enabling user modules to be executed in real-time. APPEX is the ideal platform to demonstrate the benefits of TwinCAT 3 for the packaging and process sectors.”

TwinCAT 3 makes the convergence of IT and OT a reality. It fulfils the fundamental principles of an open, highly scalable control system, and provides several key advantages, including the ability to develop, build, and debug code on-the-go without the need for hardware. It enables proof of concept before committing resources and offers a wide range of interface options - all at a cost-effective price with a free development license.

There are also added innovations in TwinCAT software - including industry specific functions (i.e., plastic processing) as well as advanced features for TwinCAT HMI. Beckhoff controllers feature many open interfaces, and communicate easily with other third party hardware via Ethernet/IP, Profinet, ModbusTCP or OPC-UA, to name a few.

“We look forward to showcasing TwinCAT 3 at APPEX – it boasts big benefits, and we are very proud to bring this revolutionary technology to the market,” she concludes.

Website: https://www.beckhoff.com/en-au/