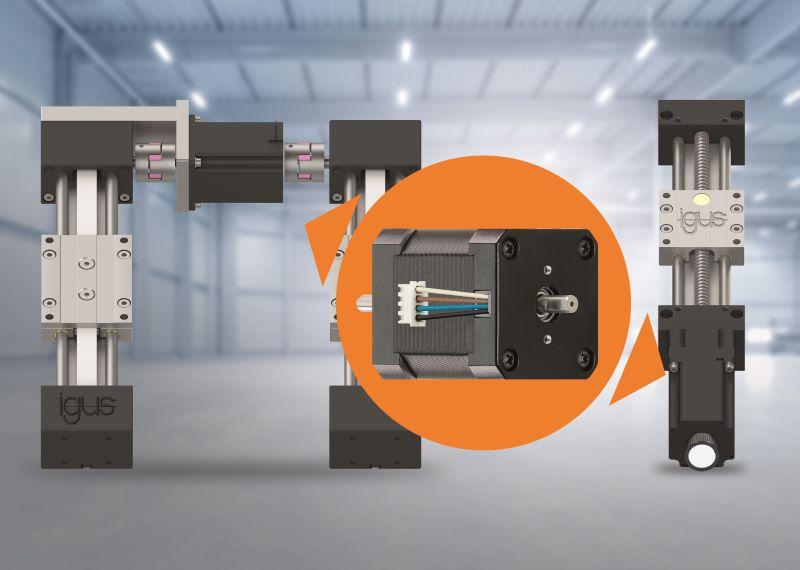

New motor for drylin linear axes ensures a space-saving and cost-effective drive for two mechanical loads

Cost-effective automation in a confined installation space. To provide an easy introduction to automation, igus has now developed a new double-shaft stepper motor for its drylin linear technology. It can be used to drive two linear axes. Another possible application is the installation of a hand wheel on the second drive shaft. In an emergency, users can turn the motor by hand. Manual zero point calibration is also possible.

If precision and controlled movements are required in drive technology, the stepper motor is the tool of choice as it moves to the desired position with millimetre precision. This is particularly important for applications in automation technology, at transfer stations and in case of format adjustments. For the first time, the drive technology specialist igus has now developed a double-shaft stepper motor for its drylin linear axes. This motor is characterised by its versatility and performance. The double-shaft stepper motor is a special type of stepper motor as it has two output shafts. "This design offers greater flexibility in the connection and drive of mechanical components," explains Rene Erdmann, Head of the drylin E Business Unit at igus GmbH. "We can now drive two mechanical loads, such as two parallel linear axes, with just one motor." This not only saves space, but also reduces costs as the motor is available at the same price as a single stepper motor and the user does not have to purchase a second coupling.

One motor, three functions

In contrast to conventional double-axis drives, where the motor is installed at the side and can cause space problems, the double-shaft stepper motor is located between the axes, making optimum use of the available installation space. Another advantage of the double-shaft stepper motor is the option of mounting a hand wheel at the second shaft end. This means that the motor can also be turned by hand so that users can manually set the zero point of a linear axis. In addition, they can adjust a self-locking lead screw axis manually by turning the hand wheel, for example in the event of a power failure. This is particularly important in areas such as entrances or doors. Apart from stepper motors, igus offers EC/BLDC and DC motors from €38 in its online shop. The suitable igus motor output stages with the name "dryve" are available starting at €70. The accompanying intuitive software is free. Powerful control systems with bus connection and integrated web server are also available.

Find out more about the new igus motor at:

https://www.igus.eu/info/n23-e-motors-stepper-motors-double-shaft