If you look at your Preventative Maintenance (PM) tasks, do you ever wonder where they came from? We recognise seriously engineered assets like ships and planes and the process of asset management and reliability engineering, designed to evaluate the risks and wear out characteristics of the asset over its life cycle and either check something, measure something, or take some actual action, (invasive maintenance). This is readily observed in structured industries, where the resulting schedule is tightly and technically controlled. Generally, we could trace the origins of a schedule, for instance, helicopter rotor blade change outs, to some form of deterioration study and high science.

For the rest of us, a valuable starting point for creating or managing a maintenance plan is the manufacturers operating manual, (a point referenced in regulations). However, while a great starting point, the maintenance instructions must be taken with a grain of salt. Whilst the manufacturer is perhaps providing the benefit of their global experience, some are ensuring the machine does not break before the cheque clears or have a strategy of selling you 2-3 times the capital value in spares over the asset life.

Whatever the source of PM routines, even highly technical industries suffer at the coalface from a plethora of additional PM Tasks that deserve some form of challenge from the Maintenance Planner. These tasks are generally easy to spot; the emphasis on check, check, check, and a lunar (monthly, six monthly, yearly) frequency. These are FAT routines, (fear and tradition). Scratch the surface and you will generally find that FAT routines are created as a knee-jerk reaction to an asset failure or similar process embarrassment, opinion, or someone else’s good idea.

While they offer a peace offering at the time of shame and atonement, they leave a legacy of unchallenged work that often chokes the maintenance schedule. There is however a solution available, based on due diligence, operational science and optimisation.

The first step is to study the provenance of the task. Who created the routine, when, and why? What results have been recorded? Has anyone ever found anything to justify the check? Unless the check has traceable roots to a statutory or compliance requirement, the planner should challenge the routine, including making frequency changes (see later). Be prepared to not win 100% of these battles, but you will be surprised how much the decks are cleared when you push back with facts.

Operational science is the art of listening to your plant, using measurements and recorded data to provide a foundation for decision making. As an example, your maintenance plan calls for you to change your gearbox oil every 12 month. However, if due to the realities of the process, environment, and service conditions, the drained oil condition, (through tribology or other) is judged to be near perfect condition. This is operational science. Common sense says you should extend your oil change plan to something more than 12 months.

Optimisation is the lean maintenance science of refining the frequency of the PM task to align with the actual plant conditions, rather than arbitrary lunar statements, (monthly, 3 monthly, 6 monthly, etc). Such stagnant frequency declarations indicate opinion rather than facts. Using optimisation theory, the Planner exercises his mandate to expand or contract the PM task frequency to suit the as found history.

On one site, we checked the safety guards every month for 23 years, only finding 10 faults in that time. An argument could be formed to expand the PM task frequency from one month to four months, based on this as-found history for the plant. This is a 75% reduction in workload, entirely justifiable by the as-found results. The Planner may declare four months as the outer limit of confidence, which is a sensible application of the planning role. As planners, we have the mandate to manage. As long as the reasons for a frequency change are recorded, we are leaving a defendable history of the management decisions.

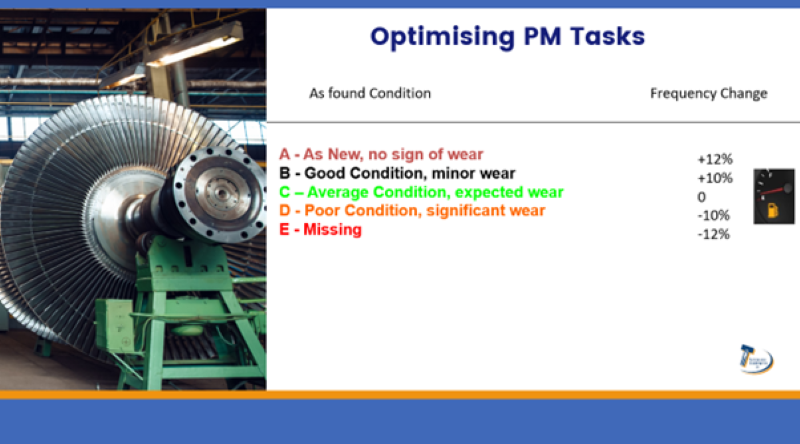

A more scientific optimisation approach is available, developed by Craig Carlyle and available as an automated toggle option in the MainTrak maintenance management system. The algorithm is based on control loop derivatives and uses simple feedback from the tradesman to nudge the task frequency either sooner or later. The steps are

+ 12%, +10%, 0, -10%, -12% depending on whether the as found condition was:

- A – As new, no sign of wear

- B – Good condition, minor wear (could have lasted longer)

- C – Average condition, expected wear (i.e., bang on target!)

- D – Poor condition, significant wear (maintained too late)

- E – Missing or destroyed

Practical experience shows that the as-found results will arrive at “C” within a maximum of 6 PM task cycles. The value is added at the workface, where the tradesman is the best eyes and ears you could ask for, and the relationship is strengthened by your investment in his/her feedback.

Returning to our example of the gearbox oil, if we had used the optimisation algorithm, the first oil change would have given us feedback of “B” – Good Condition, or a 10% increase in the task frequency (13.2 months). Subsequent task feedback would further increment the task frequency until we are changing the oil at just the right time, (condition C), reducing maintenance cost and resource allocation.

In an added value diary processing plant, this concept was used to reduce the cost for weekend process valve maintenance from $40k to just $1,200. With increased reliability!