OnRobot, has partnered with Bleinheim-based Autoline to introduce an off the shelf collaborative palletiser for SMEs in New Zealand. This industry-first solution offers same-day installation, requires no programming and can be re-deployed within minutes.

“OnRobot has successfully introduced end-of-arm tooling and sensors for robotic automation to the market by ensuring seamless integration with all major robot brands and providing a simplified and consistent user experience,” comments James Taylor Chief Commercial Officer for OnRobot. “With D:PLOY, we are taking the next logical step in simplifying the overall application rather than just focusing on individual components within the robot cell.”

Founded in 2018 in Denmark – more than two decades after the first collaborative robot (cobot) came onto the scene - OnRobot identified a need for quality cobot hardware. “With so many cobot manufacturers coming onto the scene, we recognised a need for a reputable manufacturer that could provide all the complementary physical hardware required.”

From two and three-finger grippers to sanders, vacuum, polishers, vision sensors and more, OnRobot provided solutions for a broad range of applications and tasks. “No matter what the application or task, we have a solution for you.”

OnRobot continues to evolve with the ever-changing needs of the market. “Our vision is to be the worldwide leader in collaborative applications,” shares James. “And while we remain ever committed to developing and enhancing OnRobot’s hardware, our sights are firmly set on transcending the norm to deliver a total solution. More than that, we want to make it simple for all producers or manufacturers to use robots by removing the barriers to entry which are cost, complexity, and inflexibility.”

D:PLOY boasts big benefits

The missing piece of the puzzle comes in the form of D:PLOY by OnRobot - the industry’s first automated software platform for building, running, monitoring, and re-deploying collaborative applications.

“Our goal is to ensure that no matter what robots customers choose to use, they will always have a consistent OnRobot experience,” he says. “We recognise the fact that the end-user has a desired outcome. They aren’t necessarily focused on the branding but rather on the required output. Their challenges are centered around time and cost – and more specifically when it comes to changing box sizes.”

According to James, the ultimate peace-of-mind lies in D:PLOY’s same day installation, changing an application or box size within minutes and the quick changeover of a production line. “This enables manufacturers to automate applications with robots that they have not been able to in the past due to the cost and time needed for production changeovers.”

“Today, for example, most palletising is done manually due to the high mix nature of production lines with one line often changing productions or box sizes. With D:PLOY, changeover can now be reduced to only a few minutes, which means that automating tasks with robots is now achievable and affordable since the application cell can automate multiple palletising tasks.”

Why New Zealand?

Speaking to OnRobot’s investment in New Zealand, James shares that many small to medium-sized manufacturers are facing workforce challenges and require a cost-effective solution for high-mix palletising applications.

“New Zealand is privy to high labour costs and labour shortages. As a developed country, the majority of the workforce isn’t interested in undertaking in menial, strenuous labour tasks associated with palletising and this is why a high value proposition like that of D:PLOY will be well-received by the market.”

He shares that OnRobot’s partnership with Autoline delivers a unique advantage to the local market. “We partner with local companies who can best serve the local market – this is our tried-and-trusted global model. Autoline are the industry experts, and we are there to support them and keep them flexible by providing a quick-to-deploy, always available solution.”

A winning partnership that makes automation accessible to all

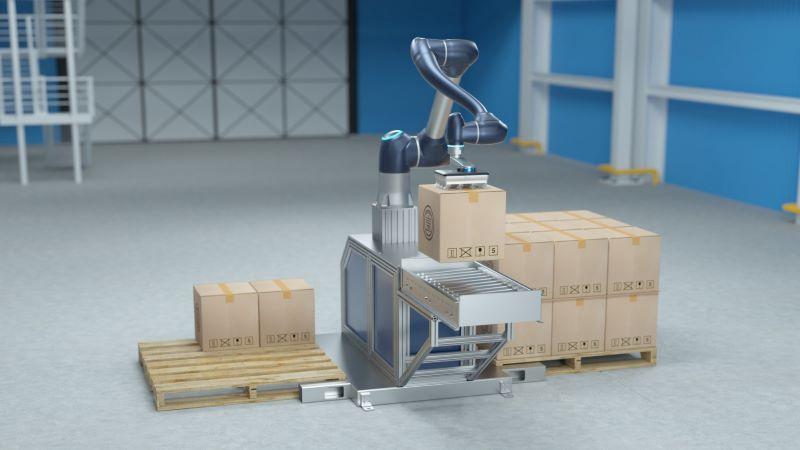

Autoline specialises in robotic welding and palletising solutions, making them a natural fit for OnRobot. Oakley Fisher Business Development Manager for Autoline believes that the launch of Auto-CoPal will reduce the barriers to entry – particularly for SMEs.

“The Auto-CoPal fills a gap in the market for a high-quality cobot palletising solution. Built and assembled in New Zealand with OnRobot components and Doosan Cobot arms, it provides a reliable and efficient palletising system,” he says.

Speaking to a key challenge faced when developing the Auto-CoPal as a complete solution, Oakley says that while most cobot palletisers for the international market are designed around a 800mm x 1200mm pallet, New Zealand has a requirement for 1000mm x 1200mm. “We needed to carefully consider the design when developing this solution.”

The success of the solution is underpinned by the winning partnership, as Oakley explains: “Our relationship with OnRobot has been crucial. Without their components and support, we couldn't have developed our cobot palletiser solution. They have been essential in bringing everything together.”

The Auto-CoPal can handle payloads up to 25kg and offers a reach of up to 1700mm. It comes complete with a Doosan cobot arm, various OnRobot tooling options and a simple single-phase power supply. The solution is now available for an introductory price of NZ$119,260+GST.

“We are pleased to partner with Autoline to bring cutting-edge, easily accessible technology to New Zealand. We believe that it will be well received and is set to shake up the market as we know it” concludes James.

Website: www.onrobot.com