In the competitive food and beverage sector, achieving operational efficiency is key. As a long-standing supplier to the sector, Bonfiglioli understands that customers are not only looking for equipment to meet strict hygiene standards but also to streamline processes.

“Manufacturers in the food and beverage sector need to balance a host of daily challenges – from the production line right through to the warehouse, all while reducing downtime and operating costs,” says Martin Broglia, Managing Director of Bonfiglioli Australia and New Zealand.

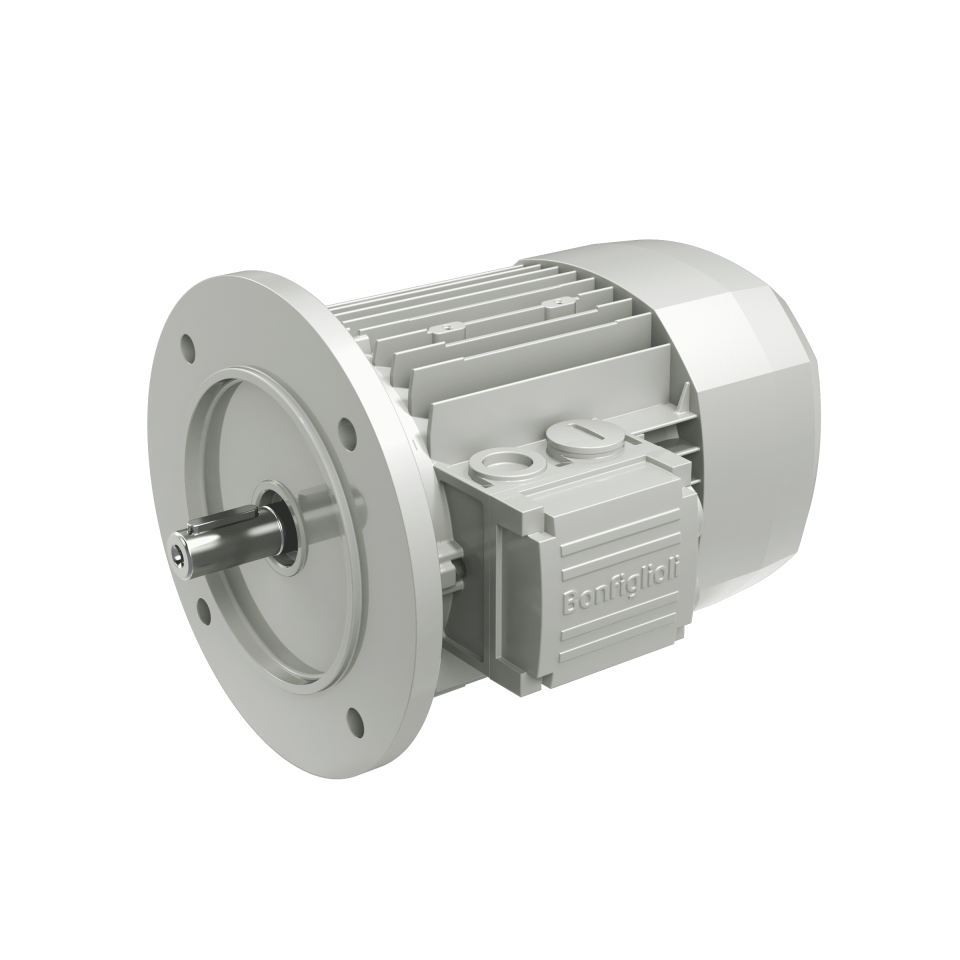

“It’s for this reason that Bonfiglioli developed the BSR Series synchronous reluctance motor.”

The BSR Series will be introduced to the local market for the first time at the upcoming 2025 Foodtech Packtech & MHL Expo - taking place from 2-4 September 2025 at the Auckland Showgrounds in New Zealand.

"The Expo offers a valuable opportunity to engage with customers and potential partners whilst showcasing how solutions like the BSR Series will help support food processing, logistics and warehousing, as well as materials‑handling," says Martin.

High-efficiency, low-maintenance performance

Martin explains that the BSR Series is an energy-efficient alternative to traditional induction motors, suitable for use in a wide range of applications – from crushing and conveying to milling.

With efficiency levels up to IE4, a compact footprint and lower maintenance needs, it’s proven to be a reliable, cost-saving and eco-friendly choice for the food and beverage industry. And with its standard IP55 (and optional IP56) food-safe protection rating and hygienic housing design, the BSR Series also stands up to demanding wash‑down routines. In addition, its sensorless control design reduces internal components, minimising the risk of food or beverage contamination.

Available in two application-specific packages

Paired with the Active Cube 410 frequency inverter, the BSR Series is available in two specialised configuration packages:

- High Efficiency Package (IE4): Ensures a marked decrease in energy consumption. With no rotor losses and reduced heat build‑up, this design improves machine reliability and extends bearing life. This package is suitable for the replacement of induction motors, usually without the need for extensive mechanical modifications. It’s ideal for use in pump, fan, conveyor, dosing and mixing applications.

- High Output Package: Delivers the same power in a smaller frame. It’s ideal for compact machinery, automated handling systems and space‑restricted food & beverage lines.

“In combination with the dedicated Active Cube 410 control, the BSR motor solution delivers maximum torque and responsiveness through precise flux control and enables high efficiency - even with partial loads,” explains Martin.

The BSR Series is available in six frame sizes - from IEC71 to IEC132 - covering a power range of approximately 0.37 kW to 18.5 kW. Built for durability, mechanical resilience and a long service life, it’s a solid choice for demanding food, beverage and warehousing environments where reliable performance is non-negotiable.

“We’re excited to be presenting this robust, energy-saving solution to the local market and look forward to the upcoming show,” concludes Martin.

The BSR Series will be exhibited at the 2025 Foodtech Packtech & MHL Expo (taking place from 2-4 September 2025 at the Auckland Showgrounds). Bonfiglioli will be located at stand J23, showcasing a number of innovations for the food processing and packaging sector. Free registration is now available at the Expo website: https://foodtechpacktech.co.nz/.