The frustration of trusting in a weather app that forecasts sun, only to be drenched with rain, is familiar to everyone. A similar issue arises in material characterisation. Without accurate data, modelling outputs often fail to match reality. Here, Andrea Incardona, application engineer at materials testing instrumentation manufacturer Instron, explains how dynamic drop testing gives material developers confidence in their prototypes’ viability.

Computer aided engineering (CAE) simulations require high-quality, well-defined and extensive data to yield reliable results. Early characterisation work establishes basic properties like density, stiffness and tensile strength.

Quasi-static testing remains fundamental, providing reliable outputs at ultra-low velocities. However, it is less effective under impulsive loads, forcing scientists to extrapolate from low velocity data.

The financial risk of pursuing a formulation that fails to deliver required properties is a great concern for materials developers. In industries using rigid plastics, films, other polymers and composite materials, absolute reliability in material properties is non-negotiable.

Safety is also key. In safety-critical industries like aerospace and automotive, dynamic testing is often mandated to meet standards such as the Underwriters Laboratories (UL) family. For example, UL2580 demands dynamic testing of the polyethylene dividing films in EV batteries to ensure safe separation of electrodes.

Dynamic testing goes beyond compliance. Advanced instruments enable flexible experiments beyond standard frameworks, supporting OEM internal specifications and alternative material assessment. Resisting advances that make dynamic testing accessible risks leaving characterisation behind evolving sector demands.

Challenges with dynamic testing

Dynamic testing has historically been limited. Instruments are expensive and the activity niche. However, high-speed deformation and failure occur within milliseconds, too fast for traditional sensors which would reduce the output accuracy.

Several dynamic testing methods exist. Split Hopkinson Pressure Bar (SHPB) measures high strain-rate mechanical properties, while Pendulum Impact Testing (PIT) assesses fracture toughness. Combined with high-speed imaging or Digital Image Correlation (DIC), these methods provide elongation and displacement data to predict failure modes.

Drop tower tensile impact testing

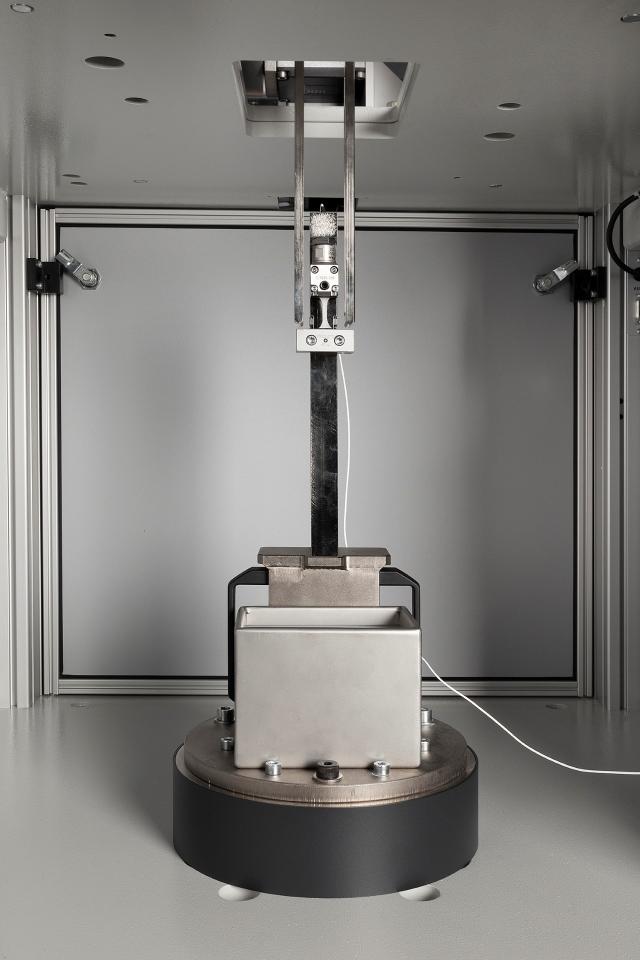

Drop tower tensile impact testing is a developing measurement field that determines tensile strength, elongation, displacement and the stress-strain curve. a sample is held in a vice while a striker drops at a predetermined velocity measuring energy absorbed until failure.

This method reduces reliance on extrapolated data from quasi-static tests. Comprehensive profiles combine drop tower results with other tests and numerical modelling to predict behaviour across a broad strain-rate spectrum. Accurate simulations accelerate development and increase confidence in material design.

What does drop tower testing add to materials characterisation?

High-speed imaging captures failure propagation in milliseconds. When paired with force sensors, it allows analysis of the transition from elastic to plastic deformation and full fracture. Combining with digital image correlation (DIC) maps localised stress and strain by tracking a visual pattern on the specimen, offering granular analysis.

Variable sampling frequency is also essential. Brittle materials break quickly, needing high frequencies to detect force profiles, while ductile materials require lower frequencies to capture the full curve. Advanced drop tower instruments provide wide frequency ranges and over 60,000 acquisition points.

Quasi-static testing remains useful, but feeding models with approximations is no longer enough. Drop tower testing delivers reliable experimental data, enabling safer, more consistent products and reducing investment risk.

With instruments like Instron’s 9450 High Energy Drop Tower, R&D teams can earn an advantage in material development and compliance with standards.

www: www.instron.com