|

HYDRAULIC systems create pressure and force, and that means danger exists to those using and servicing hydraulic machinery. Safety regulations require certain hydraulic equipment to provide a means to minimise the danger and protect people from injury. Hyspecs stocks monitored safety valves and accumulator unloading valves which were designed to do just this. Monitored safety valves are used in Australian Risk Category 4 applications. By using these monitored valves to confirm that the directional hydraulic control valves have been isolated, the powerpack pump can be left running while the operator has access to the machinery. The valve spool position is monitored by a limit switch. Two cetop valves are used in series typically in a ‘block and bleed’ configuration. The limit switch confirms that the valve has shifted into its fail-safe state – in this safe state pressure from the hydraulic pump is blocked and pressure to the directional hydraulic control valves is bled to tank. Hyspecs designs custom manifolds that incorporate these valves along with other cartridge valving. To determine if an accumulator may fall under the requirements of a pressure vessel, contact Hyspecs for a copy of the Accumulator Regulations Guide. Note that this is a guide only and regulations may be subjective. Along with accumulators Hyspecs also stocks EPE accumulator unloading valves/safety blocks (B20FB315GRP) which are a requirement under the regulations. Accumulator unloading valves provide relief protection and a safe means of unloading the accumulator when the machine is not in operation. This is especially important when servicing hydraulic equipment with accumulators attached. Talk to Hyspecs about obtaining the full EPE AS Accumulator catalogue. |

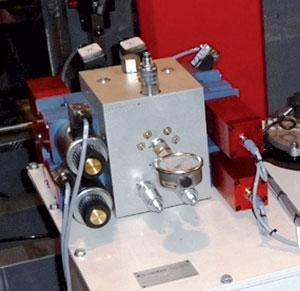

The B20FB315GRP has a manual dumping mechanism and Hyspecs has designed and manufactured a bolt on block (HS9551AS with cartridge SV08-21) to give the B20FB315GRP an electrical unloading option of accumulator pressure when the machine is shut down.• reader enquiries quote: D090626

Email: nick@hyspecs.co.nz

|