Hot melt over-moulding process

COMPANIES looking for a fast, low-cost over-moulding service for parts such as electrical connectors and PCBs, need look no further than AZCO.

AZCO has invested in a Moldman 8000 machine which carries out the low pressure moulding of connectors and electronic parts utilising polyamide hot melt resins. According to AZCO’s Colin Hooper the advantages of this system includes:

• Very low cost tooling

• Short lead times

• Small batches are economical

• Waterproof connections and circuits at a very

low cost

• Stain relief is built-in

• Electrical insulation

• Mechanical protection of parts from contact or

vibration

• It’s safe on PCBs – complete waterproof

encapsulation possible

• Resistance to chemicals

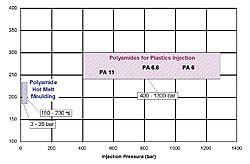

Low pressure moulding differs from plastics injection moulding in its application temperatures and pressures (as shown in diagram). Application machinery and moulding tools, like AZCO’s Moldman 8000 are therefore less complex and operate at a far lower cost level, explains Hooper. The cost-effective production of small batches is arguably the greatest benefit.