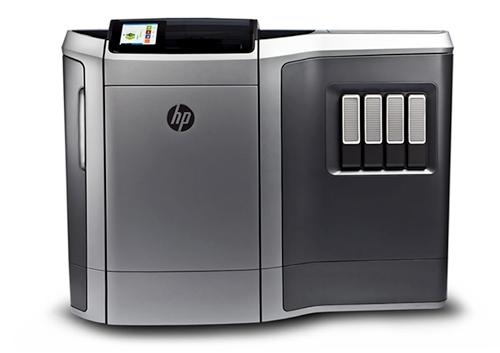

HP unveiled its Multi Jet Fusion 3D printing technology in October. Derived from a combination of existing inkjet and fusion processes, the firm aims to introduce the first printers in the second half of 2016. Pricing is not available but they will be targeted at enterprises and service bureaus, not consumers.

HP’s inkjet technology uses thermoplastics, jetted materials and radiant energy. The results are claimed to be mechanically strong and highly precise, similar to thermoplastics formed by selective laser sintering (SLS) processes.

The firm indicates production rates are expected to be about 10 times faster than SLS. However, it is too early to know whether such high productivity applies to all use cases or is it peak performance for certain situations, materials and/or products.

The technology resembles a binder inkjet process, but the inkjet head deposits a thermal fusion liquid. A heating element transfers energy into the fusing agent, causing localized fusion of the thermoplastic. The printhead also deposits a second material layer, promoting fine detail and surface finish.

Other materials and chemicals can be deposited with the fluids, enabling the infusion of metals, ceramics and chemicals into the build material. Separately, HP has demonstrated precision parts with good mechanical properties and reasonably smooth finish that were printed using optimized thermoplastics.

The system draws from HP’s expertise in inkjet hardware and chemistry for the 2D digital printer market. Based on initial market research, the material is a black thermoplastic but development of colored materials is underway. The materials and chemicals reportedly will not require special handling for safety purposes.

Potential uses include new product development, prototyping and functional testing, mass customization and the creation of alternative product designs without limitations of traditional manufacturing techniques.

HP has a first product in development, but does not expect models to reach the market for two years. While some were expecting a rapid launch, HP feels that engaging in partnerships with customers and vendors will help it refine the technology and determine the best initial applications.

HP’s partner-based approach provides opportunities for third parties to collaborate on and develop the printers. The idea of encouraging engagement and innovation from outside of HP seems like a very non-native thing for HP to do but the concept was successfully applied to the development of its very high speed inkjet press product line.

Rivals have plenty of time to innovate, making HP’s strategy risky. It must ensure the printers’ material range and capabilities, productivity and pricing are not just significantly better than today’s technology but better than the technologies and 3D printer offerings that will be in the market in late 2016.

Printer market

3D printer unit shipments will grow at a compound annual growth rate of 106.6 per cent through 2018. Corresponding annual average spending will grow at 87.7 per cent for the same period. Sales will exceed US$13.4 billion in 2018 as consumers and organizations rapidly adopt 3D printers for home and business use.

Source / Gartner.com