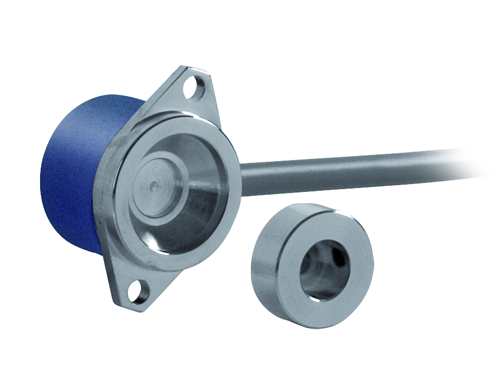

The contactless and bearing-less rotary incremental EMI 22 and EMI 55 encoder series with magnetic technology integrated are the ideal solution for harsh environment applications and for industrial systems that require high speed and resistance (i.e. iron and steel, glass, ceramics, marble, wood and textile processing industries) and, at the same time, an excellent reliability and a high enclosure rating from dust and liquids. The key feature of EMI 22 and EMI 55 series is the integration of the magnetic principle also to the fixing system of the encoder to the motor shaft: thanks to the application of a magnet on the shaft, there is no physical coupling between the device and the machine, which implies several benefits:

- No wear and long-lasting life of the encoder;

- Extremely sturdy and compact design;

- High rotation speed (10.000 rpm);

- Excellent resistance to vibrations (10 G, 10 ... 2000 Hz) and to mechanical loading;

- Wide range of operating temperature (form -40°C to +125°C max);

- Very easy mounting.

For further details or to enquire about Eltra's encoder model most suitable for your requirements, please don't hesitate to contact our offices of John Brooks Ltd Contact Ph. 0800 24 34 44 or email saleswn@johnbrooks.co.nz